Industry Spotlight

Materials handling

Overcoming industry challenges

Materials handling manufacturers are using DriveWorks design automation & CPQ sales configurator software to improve manufacturing and sales processes and be more efficient.

Complex production processes

Manufacturing materials handling equipment involves intricate processes, especially for advanced technologies such as robotics and automation. Managing these complex production processes efficiently is a challenge.

How DriveWorks helps

DriveWorks automates the design and engineering processes, reducing the complexity of production. It allows manufacturers to create rules and logic that drive the design process, ensuring consistency and efficiency in producing various configurations of materials handling equipment.

Quality control

Ensuring the high quality and reliability of materials handling equipment is crucial. Striking a balance between cost-effective production and maintaining stringent quality standards presents an ongoing challenge for manufacturers.

How DriveWorks helps

By automating the design process, DriveWorks helps enforce design standards and quality controls. Consistent application of rules and specifications reduces the likelihood of errors, ensuring that each manufactured product meets high-quality standards.

Supply chain disruptions

Materials handling equipment manufacturers are susceptible to supply chain challenges where disruptions in the supply chain can lead to delays in production, increased costs, and lost sales.

How DriveWorks helps

DriveWorks allows for agile design changes. In the face of supply chain disruptions or changes in material availability, manufacturers using DriveWorks can quickly adapt product configurations without significant manual reengineering, helping to mitigate the impact of disruptions.

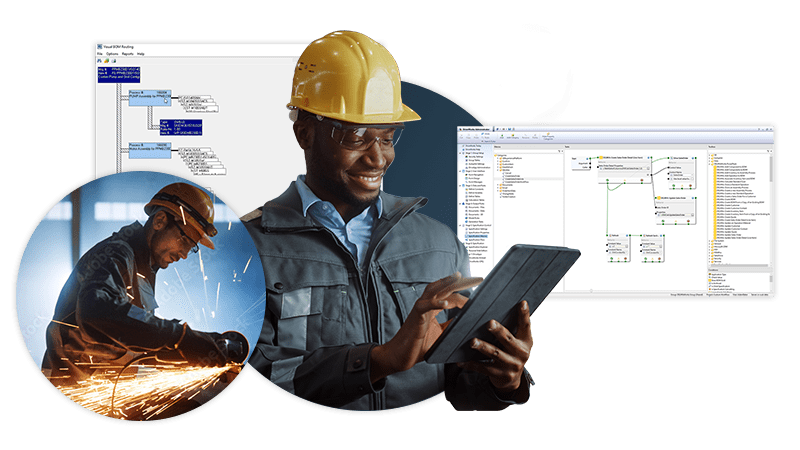

Customization demands

Customers increasingly require customized solutions to meet their specific materials handling needs. Manufacturing equipment that can be easily adapted to different applications without significantly increasing production costs or lead times is a challenge.

How DriveWorks helps

DriveWorks CPQ solutions excels in handling customization demands. It allows manufacturers to create configurable product models, empowering customers or sales teams to customize materials handling equipment according to specific requirements while ensuring that these customizations remain within predefined parameters.

Environmental compliance

Meeting environmental regulations in the manufacturing process, such as reducing energy consumption and waste, adds complexity to production processes and may require additional reporting.

How DriveWorks helps

DriveWorks can be implemented to include environmental considerations in the design process and use materials in the most efficient way possible. This ensures that designs comply with environmental standards and regulations, helping manufacturers meet sustainability goals in their production processes.

Managing customer expectations

Communicating the customized features and functionality of complex materials handling solutions is challenging. Customers need to be able to clearly see product options and variants to be able to make informed buying decisions.

How DriveWorks helps

DriveWorks 3D visual configurators help in visually communicating complex product features to customers. They allow manufacturers to quickly adapt to changing customer expectations by facilitating the integration of new features and technologies into customized product configurations. This agility is essential for meeting changing customer demands.

Customer Success Story

Rademaker

Learn how Rademaker have reduced engineering time to 15 minutes and increased quality using DriveWorks.

Get started with DriveWorks

Getting started with DriveWorks is quick and easy.

Get started for free

DriveWorksXpress is free inside SOLIDWORKS and you can try DriveWorks Solo free for 30 days.

Explore solutions

Learn more about how the features in DriveWorks can be utilized.

Compare software

Compare the features in DriveWorksXpress, DriveWorks Solo, and DriveWorks Pro.

Request a demo with a technical specialist

Fill out the form below and a member of the DriveWorks team will be in touch.