In our blog, How Digital Transformation is Changing the Manufacturing Industry, we explored emerging trends in digital transformation and industry 4.0, looking at how the manufacturing industry is being transformed by a revolution of smart factories, automation and big data.

Powering this digital transformation is the development and integration of software.

Going Digital

Going digital is all about streamlining business processes, driving productivity and innovating one step at a time. Entrepreneur Europe reports that the point of digital transformation is not to take companies from paper processes to hyper-advanced and complex digitalized alternatives. Instead, many components of digital transformation are subtle and take time.

A lot of businesses fear the changes digital transformation brings because they think it means updating entire infrastructure with new systems, new technology and new processes, however, digital transformation isn’t just about transforming factory floors with robots and automation.

Alongside these devices, software is developing too, supporting the introduction of smart, tech-driven solutions and playing a key role in transforming industries.

Influencing Industries

A great example of the impact software can have is how Laing O’Rourke have digitally transformed the bridge industry.

Software enhances, expands, and restructures the way organisations work, influencing industries and having a huge impact on digital transformation throughout manufacturing.

Laing O’Rourke collaborated with Tony Gee and Cambridge University to develop a unified digital delivery process for the entire bridge industry.

The research group have introduced standards to simplify a complex process. The outcome is a set of best practices for manufacturing, assembly and design, to ensure consistent data formats and reduce manual processes required between stages.

Using SOLIDWORKS 3D CAD and DriveWorks Design Automation and Configurator software, Laing O’Rourke have built tools to digitise bridge design.

This project has dramatically reduced the time taken to reach the final design, construct and complete a bridge and has transformed the entire bridge industry through the use of software.

The time savings could see bridge designs produced in days or weeks instead of months and years. Rolling out the project will increase efficiency and capacity across the entire industry.

Integrated Processes

In order to be successful, software needs to work in harmony with each other and with current business processes.

To streamline processes, more and more companies are using Enterprise Resource Planning (ERP) systems to manage integrated applications.

ERP connects core business processes and improves efficiency of production, as well as the operation of the entire business.

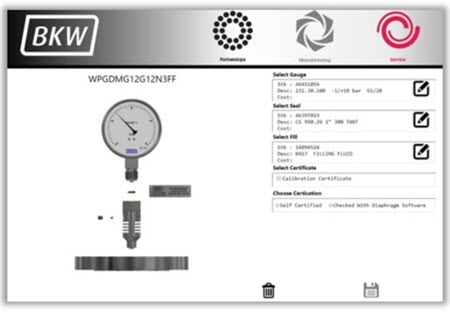

BKW Instruments, a company who provide equipment and instruments to various industries in the UK, developed a web-based platform that allows their company to interact with the SYSPRO ERP system securely from any device, anywhere in the UK.

The application BKW developed was created in DriveWorks and enables them to organise and speed up everyday business processes and tasks.

Logging and processing sales enquiries has gone from 3 hours to 30 minutes and their internal sales team are creating quotes twice as fast as before, resulting in a 100% increase in productivity!

Their customers are benefitting from quicker turnarounds and better service too.

BKW has successfully met all their business objectives, resulting in significant time savings, increased productivity and better customer experiences.

Digital transformation is changing the way companies work across all departments. Digital transformation provides a perfect opportunity for businesses to replace traditional ways of doing business with other sophisticated digital technologies to embrace the new digital world.

The role of software in the manufacturing industry is only going to continue to grow. By embracing new technologies and software, businesses can increase efficiency, improve accuracy, streamline business to consumer relations, boost speed, and allow for a wider range of products.

This is the second blog in our new digital transformation series. Each week we will be sharing our insights about the importance of embracing digital transformation and automation. Keep reading to learn more!