For many manufacturers, ensuring consistent design quality and regulatory compliance are key requirements. Selling custom products that adhere to different quality and safety standards, depending on how they are being used and where they are being sold, can be complex. Regulations and standards can vary locally and internationally so manufacturers need to be able to confidently and consistently meet different customer requirements.

Importance of design consistency in manufacturing

For manufacturers of custom products, maintaining design consistency across different products, sectors and countries is critical for product quality and customer satisfaction. Consistent design quality promotes trust, reduces errors and rework and lowers production costs.

DriveWorks ensures consistency in design by using standardized rules and parameters that you build into your configurator. The rules-based technology guarantees that design standards are met at every stage of the process, ensuring the maintenance of product design quality across custom and standardized components.

Additionally, DriveWorks enables manufacturers to embed quality control checks within each stage of their design automation process, reducing the risk of errors and ensuring that products meet both industry standards and customer expectations.

Meeting complex regulatory requirements

Compliance with industry regulatory requirements is non-negotiable. Failure to meet relevant safety, environmental or industry-specific requirements can have serious consequences.

DriveWorks enables manufacturers to embed regulatory requirements into their design rules. This ensures that each custom product generated through the automation process complies with relevant regulations.

Regulations can change frequently and ensuring products are designed and produced to meet current regulatory standards across different markets is an ongoing challenge.

Manufacturers and sales teams must navigate compliance requirements, which may vary across regions.

DriveWorks can be configured to ensure that designs automatically comply with the latest regulatory standards. This reduces the risk of non-compliance and streamlines the process of adapting to changing regulations, ensuring that products always meet the necessary certifications.

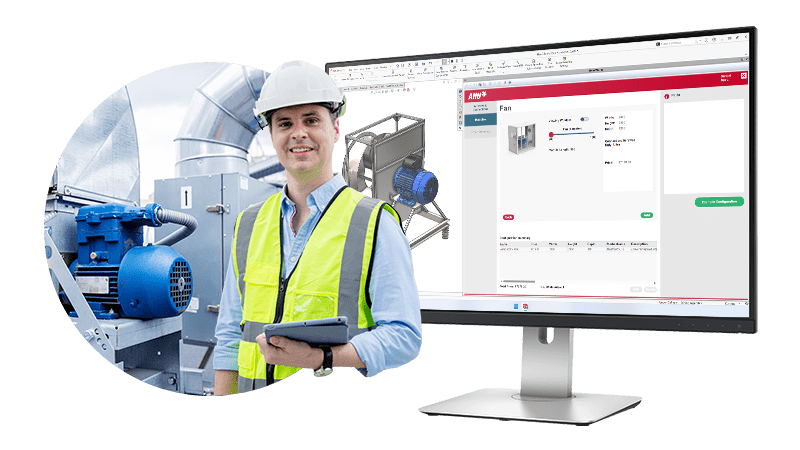

CPQ and guided selling tools in DriveWorks enable sales teams, customers, and distributors, to access the latest compliant configuration options. With the knowledge that all product configurations are compliant, sales teams and resellers, are able to sell confidently, knowing that product configurations are valid and accurate.

Selling across industries, regions and countries

Many manufacturers sell across multiple industries, regions and countries, each with their own particular regulatory requirements. This can be challenging to manage and the risk of non-compliance increases with complex custom products.

Using DriveWorks, businesses can confidently expand into and sell in different markets knowing their products will meet all of the necessary requirements. The rules-based technology inside DriveWorks means you can ensure designs are compliant according to different industry standards, and different regional and country requirements.

Using DriveWorks to meet local regulations and international standards

EBD is a company based in Wales that specializes in manufacturing and supplying bespoke steel doors that meet the highest standards of performance, compliance and functionality. With key clients worldwide, they take pride in their ability to accompany their clients through every step of the process, from the early stages of design, to when the door is delivered and installed at site. From fire-resistant doors to acoustic doors, security doors and escape doors, they provide tailored solutions that are designed to perform.

Using DriveWorks technology, EBD ensure their products meet both local regulations and international standards.

“Manufacturing fire rated steel doors for both the UK and European markets requires strict adherence to both local regulations and international standards. At EBD Steel Doors, the scope of our product offer and our commitment to provide our customers with bespoke doors designed for their specific application, the adherence of the design to these standards can be complex. Using DriveWorks, we are easily able to control all aspects of the door that are affected by these standards (such as limiting the size of the door and the selection of ironmongery and other door furniture based on previous selections). This ensures that the design output is fully compliant with these standards and all the design rules are applied”

– Design Manager, EBD Steel Doors

Start your free 30-day trial today

Powerful SOLIDWORKS® part, assembly, and drawing automation – start your 30-day free trial of DriveWorks Solo today.