As we look ahead to 2025, we believe several key trends will shape the manufacturing industry over the next 12 months. From technology solutions driving sustainable business practices to customization and localized manufacturing, how custom products are designed, sold, and manufactured, will continue to evolve. Manufacturers will increasingly turn to digital tools to help them overcome a number of challenges including the recruitment and retention of skilled staff and the increasing demand for customization.

In this blog, we explore the key trends that we think will define manufacturing in 2025 and look at how manufacturing companies can respond to these trends and position themselves to increase sales and maximize profitability.

Technology driving sustainable manufacturing

The manufacturing industry as a whole has a huge role to play in achieving the goal of net zero by 2050. Globally, manufacturers are responsible for consuming 54% of the world’s energy resources and one-fifth of carbon emissions.

Technology solutions will help businesses to develop more sustainable manufacturing practices. In particular, design automation solutions enable manufacturers to reduce bottlenecks and streamline processes, resulting in reduced volumes of rework and wastage.

Improved levels of data monitoring and reporting will enable manufacturers to better understand sustainability metrics and identify areas for improvement where eco-friendly manufacturing practices can be adopted.

Decentralized manufacturing

In response to continuing global supply chain challenges, manufacturers will increasingly review the benefits of a decentralized, more localized approach to production. Local manufacturing models reduce the risk of delays and avoid fluctuations in transport costs.

Manufacturers will increasingly review the benefits of bringing production closer to home, reducing dependence on overseas suppliers. Decentralized manufacturing reduces lead times, promotes local employment, and ensures better quality control.

A local focus can also help SME manufacturers to appeal to local markets, with a competitive advantage over remote larger competitors who have less affinity with the local market and are more likely to experience supply chain challenges.

Attracting and retaining talent

Attracting and retaining talent is an ongoing challenge for the manufacturing industry and one which will continue in 2025. Misconceptions amongst young people that the industry is low-tech, combined with an aging workforce, have resulted in a growing manufacturing skills gap.

Digital transformation will play an important role in changing outdated perceptions of manufacturing and encouraging younger employees into the industry. The adoption of digital technology will change the manufacturing landscape, making a career in manufacturing more appealing to a wider audience.

Equally important, will be the adoption of digital tools by the current manufacturing workforce. Technical skills training will upskill existing employees, leading to improved retention rates and higher job satisfaction.

Customization

The growing demand for customization is a trend that will continue to have an impact on the manufacturing industry.

Traditional manufacturing processes have often been set up for standard products, involving a high degree of manual input and complicated workflows. To efficiently configure, design, and sell custom products, more manufacturers will adopt digital technologies to automate repetitive design tasks, streamline operations, and simplify the process of configuring and quoting custom products.

This will not only enable manufacturers to offer customized products, but they will also benefit from improved efficiencies and increased productivity.

How can DriveWorks technology help your business in 2025?

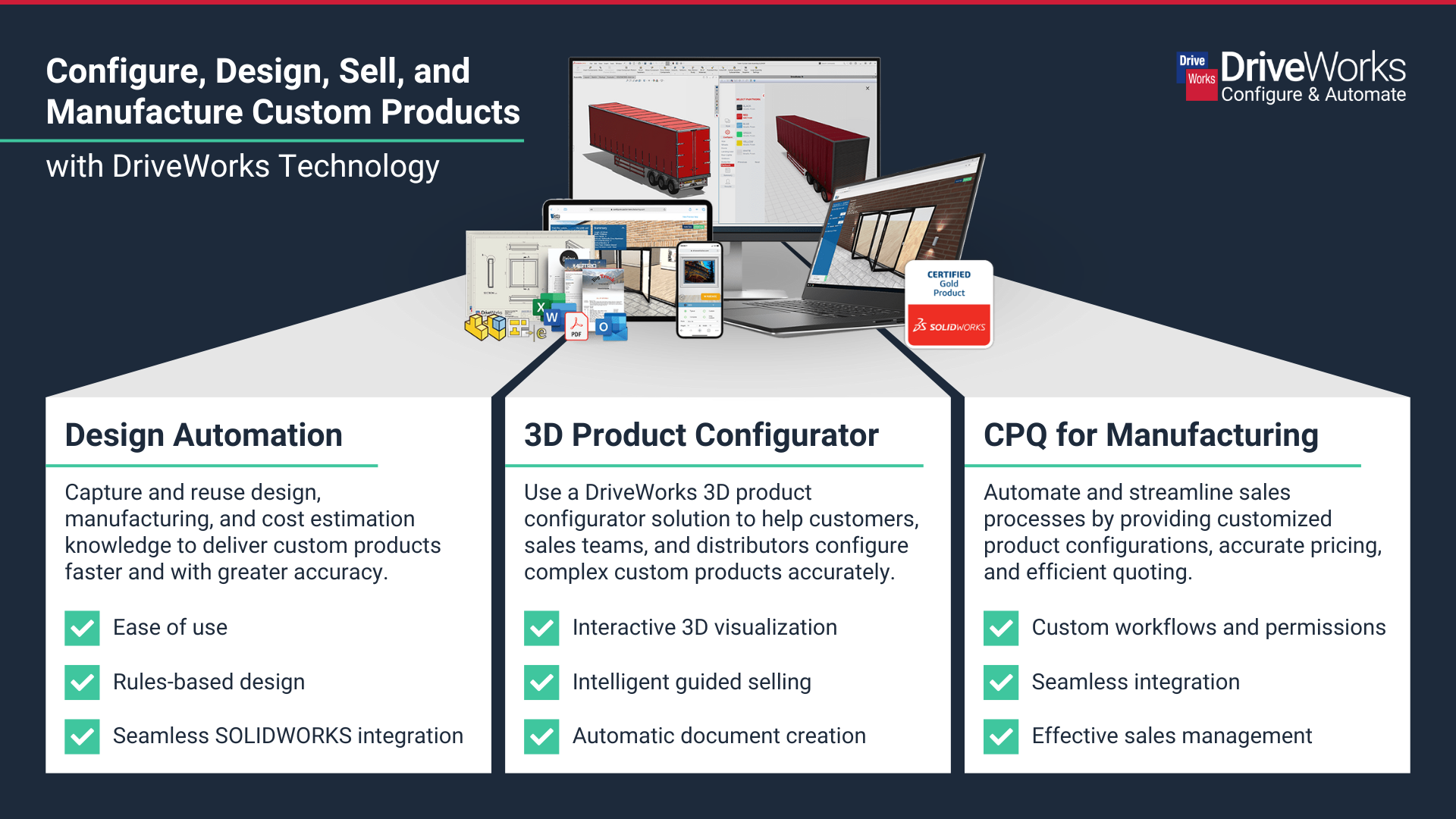

DriveWorks technology is designed to help manufacturers of all sizes and offers a suite of automation and configuration solutions tailored to meet a wide range of requirements. DriveWorks technology solutions are scalable and flexible, enabling companies to evolve their automation efforts as their business needs change.

Using DriveWorks design automation technology, repetitive tasks, and costly errors are eliminated, enabling streamlined operations that drive sales growth. Using DriveWorks 3D product configurator and CPQ solutions, design engineers, sales teams, distributors, and customers collaborate seamlessly enabling the design, customization, and ordering of products on any device, anytime.