From simple automation tasks to complex configurations, DriveWorks technology enables manufacturers of all sizes to efficiently configure, design, sell, and manufacture custom products. Maglin Site Furniture designs and manufactures furnishings for public spaces. Their product line includes custom outdoor site furniture such as benches, tables and seating, waste containers, bike racks, panels, planters, and sunshades.

Javelin Technologies, a DriveWorks Value Added Reseller in Canada, introduced Maglin to DriveWorks. Maglin was able to quickly and easily implement DriveWorks software, enabling them to successfully move to manufacturing – and to market – much faster.

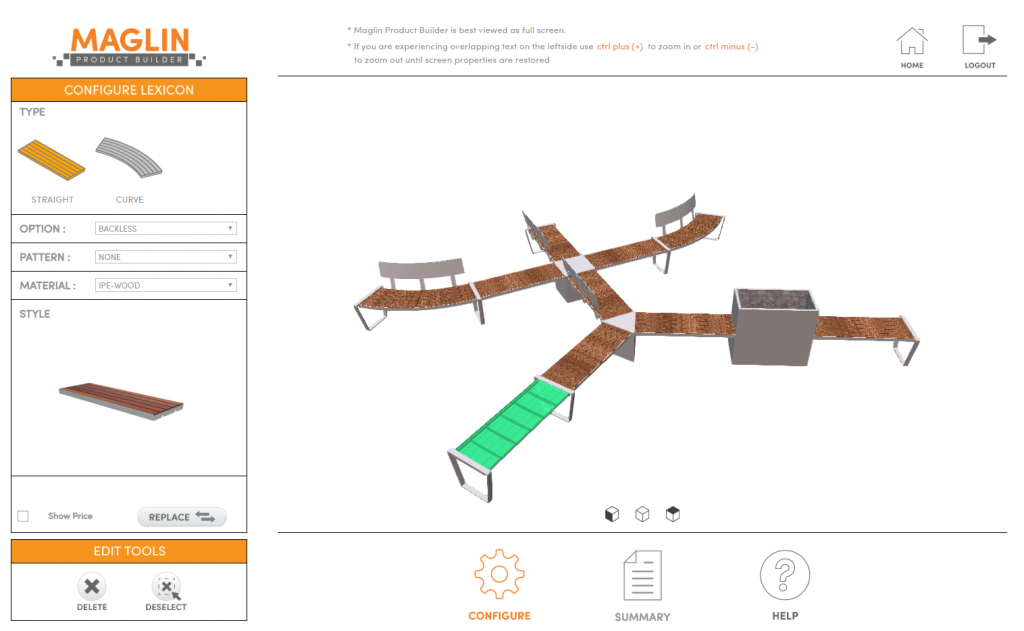

In this blog, we look at how Maglin uses DriveWorks design automation and CPQ technology to manage the design and manufacturing of its modular products, consisting of dozens of elements that can each be customized for aesthetic and functional purposes.

Making complex configurations easy

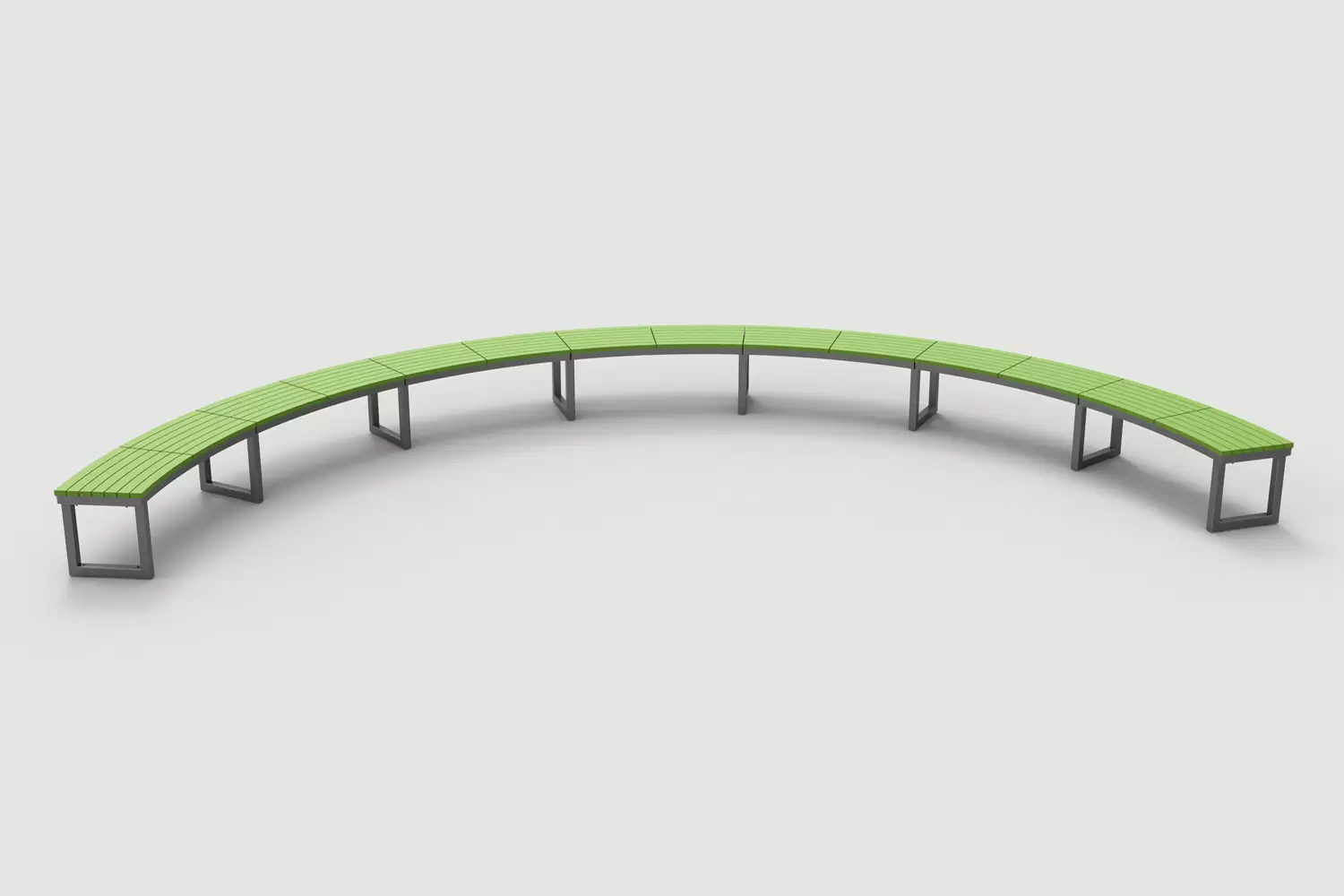

Maglin’s products are highly configurable, built to order, and available in different sizes, colors, materials, and layouts. There are thousands of possible configurations, with one of their product lines having 82,560 possible configurations.

Using DriveWorks configurator technology, customers can independently configure their products online and visualize their final design, often without spending any time with the sales team. Using DriveWorks rules-based technology, accurate prices are automatically calculated, reflecting current material costs, manufacturing complexity, and any discounts or promotions.

Their streamlined sales cycle enables Maglin to have products ready to ship in 6-8 weeks, about half the time of their competitors.

Less time spent on approval drawings

Before using DriveWorks, Maglin’s designers spent weeks creating approval drawings. With each different configuration version, a new set of approval drawings had to be created, making the process lengthy and time-consuming, taking up to 2 weeks to complete.

Using DriveWorks, approval drawings are automatically generated, showing both simplified dummy models and visually appealing customer-facing layouts. The approval drawing process now takes only 20 minutes, with customers and sales reps also able to edit the layout themselves without involving the engineering design team.

“DriveWorks has been a game changer for us as we continue to be a leader in our industry.”

Ian McAskile, Maglin CEO

Accuracy in production drawings

Before using DriveWorks, Maglin’s design team manually created drawings from a master SOLIDWORKS model. Human error sometimes resulted in inaccuracies in the drawings, leading to delays and re-work.

The team now uses DriveWorks design automation technology to automatically create accurate versions of their SOLIDWORKS drawings, without the need for any manual input. The drawing process time has been halved without any compromise to quality.

Seamless integration with ERP system

Maglin has integrated DriveWorks with its ERP system to automatically input the majority of engineering and manufacturing data, including BOMs. Previously, this process was manual and prone to error. Now, only a small number of fields require manual entry, while the vast majority are automatically populated with data.

Streamlined shipping and storage

DriveWorks is also integrated with Maglin’s freight partner database, enabling shipping details to be automatically generated. Their configurator automatically calculates the number of boxes needed for each configuration and the shipping price based on the postal code.

Using DriveWorks to streamline its design and sales processes has enabled Maglin to improve its inventory and storage management. Efficient material allocation means that items arrive and go straight into production rather than being stored in their warehouse.

Freeing up time for new product development

Spending less time on repetitive design tasks means that their design team can work on more creative outputs. The team now enjoys working on developing existing product lines and having time to think creatively about new product ranges.

How DriveWorks is helping other customers to succeed

DriveWorks is used by manufacturing companies from a range of industries. Because DriveWorks is modular, scalable, and incredibly versatile, our customers use DriveWorks in many different ways, building design automation, product configurator, and CPQ solutions to suit their needs.