Karaca Gemi Ship Windows & Wipers

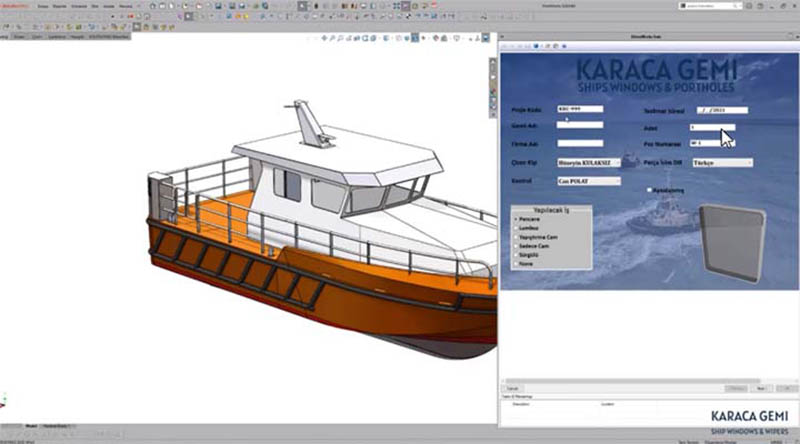

Karaca Gemi transforms its sales process and frees designers to focus on product innovation by automatically generating SOLIDWORKS® models, technical drawings, and sales documents with DriveWorks Solo

Challenge

Karaca Gemi identified the need to optimize their existing process of creating CAD data, reduce file size, provide 3D models of parts, and include important information such as net weight.

Solution

DriveWorks Solo automatically generates the order-specific SOLIDWORKS models and drawings and exports them in PDF, DWG, and STEP format ready for the customer.

Results

Anyone within the company can now configure a new order, guided by the UI created in DriveWorks. Design data, 3D models, and BOMs are automatically prepared for the customer.

Company overview

KARACA GEMI, based in Turkey, is among the world leaders in developing and producing ship windows, glass, wiper, and frame constructions. For over 12 years Karaca Gemi has offered customized window solutions for small workboats, ferries, cruise liners, fishing vessels, and commercial vessels.

Windows can be supplied with all types of special glass and window frames are manufactured from a wide range of profiles in aluminum, steel and stainless steel. Products meet all major international and national accreditations, including IS0 standards.

Karaca Gemi is focused on delivering superior quality by following the latest technological developments and ensuring customer satisfaction through maximum service and quality.

Challenge

Automating time-consuming tasks

Before adding DriveWorks to their design process, engineers at Karaca Gemi would create custom drawings from the same templates using 2D CAD. Unfortunately, the drawings lacked key information, such as net weights, and order-specific 3D models could not be shared with customers.

SOLIDWORKS 3D CAD resolved these issues but creating order-specific models and drawings involved duplicating files using SOLIDWORKS Pack and Go. This resulted in large data sets and time-consuming manual updates that tied up engineers from focusing on product innovation and development.

Karaca Gemi needed a solution to simplify the creation of order-specific sales and manufacturing data and remove expensive time-consuming tasks that could be automated.

Thanks to DriveWorks, unnecessary time-wasting is behind us and we can use this gained time to do more research & development

Erhan Kusculu, Co-Founder/CFO

KARACA GEMI

Solution

Karaca Gemi started their journey with a free 30-day trial of DriveWorks Solo.

They now use DriveWorks to automatically create custom SOLIDWORKS parts, assemblies, and drawings to meet customer requirements. DriveWorks also automatically saves the generated SOLIDWORKS files in PDF, DWG, and STEP format, ready to be sent to the customer.

By utilizing DriveWorks Solo, Karaca Gemi can quickly respond to customers with 3D models of their customized products along with key sales documents, including BOMs and quotes.

The DriveWorks form designer made building custom forms to gather product requirements simple. The forms ensure all the required information is gathered, enabling anyone to accurately configure custom products for customers.

Results

DriveWorks has transformed Karaca Gemi’s sales and manufacturing process, enabling them to respond quickly to customer inquiries with order-specific documents, data, and 3D models. The input forms they have built for their configurator make it easy for anyone to configure a new specification for a customer, even if they haven’t used them before.

Implementing DriveWorks Solo has enabled Karaca Gemi to:

- Easily send 3D models of every custom product to the customer, enabling them to visualize their product and have access to a STEP file

- Automatically create accurate order-specific BOMs

- Respond to customer inquiries more quickly

- Reduce errors in the design stage and as a result, reduce costly mistakes during manufacturing

- Standardize file naming, ensure consistency and improve organization by automatically generating, naming, and saving files into specific folders with custom names

- Focus designers on product innovation by automating repetitive, time-consuming design work

After their success with DriveWorks Solo, Karaca Gemi aim to upscale their implementation into DriveWorks Pro to take advantage of the extra features it offers. They are particularly interested in making their product configurator available online for customers using DriveWorks Live. They also want the ability to integrate DriveWorks with their PDM and ERP systems.

Try DriveWorks Pro configurator examples online

Request a demo with a technical specialist

Fill out the form below and a member of the DriveWorks team will be in touch.