The furniture manufacturing industry, is integral to numerous sectors including architecture, interior design, and retail. However, the industry faces several challenges that can impact efficiency and productivity. DriveWorks technology provides a powerful solution to these challenges by automating the design process, reducing lead times, enhancing cost efficiency, ensuring accuracy and quality, and providing scalability for growth. Furniture manufacturers are using DriveWorks design automation and CPQ sales configurator software to streamline manufacturing and sales processes, and enhance efficiency and business performance.

How DriveWorks helps the furniture manufacturing industry

Supply chain disruptions

The furniture manufacturing industry faces challenges in the supply of high-quality materials and components. Sourcing some types of wood and metal can be difficult due to changing environmental regulations, supplier relationships, and logistics issues.

How DriveWorks helps

DriveWorks enables furniture manufacturers to make agile design changes. In the face of supply chain disruptions or changes in material availability, furniture manufacturers using DriveWorks quickly adapt product configurations without significant manual reengineering, helping to mitigate the impact of any disruptions.

Labor shortages and skill gaps

Finding skilled labor for furniture manufacturing, especially for specialized tasks like furniture design, can be challenging.

How DriveWorks helps

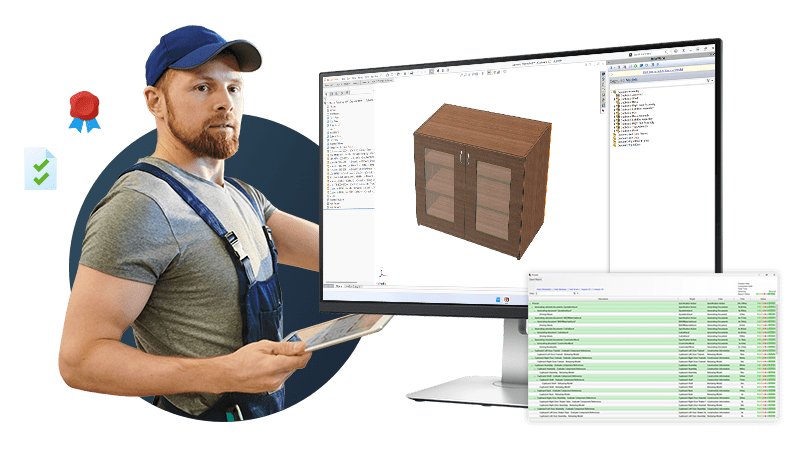

DriveWorks reduces the dependency on highly skilled designers and engineers by automating repetitive design tasks. This not only addresses the shortage of skilled labor but also frees up existing design teams to focus on new furniture product innovation.

Sustainability and environmental regulations

The demand for sustainable and eco-friendly materials requires furniture manufacturers to adopt a strategy of continuous innovation. Ensuring furniture complies with environmental regulations and standards can be time-consuming and expensive.

How DriveWorks helps

DriveWorks enables furniture manufacturers to embed compliance requirements into their design rules. This ensures that each product generated through the automation process complies with relevant sustainability and environmental regulations.

QA, QC, and product safety

Maintaining high-quality standards across all products is essential to brand reputation but can be challenging. Ensuring products meet safety standards and regulations in different markets requires diligence and adaptability.

How DriveWorks helps

DriveWorks ensures consistency in furniture design by using standardized rules and parameters. This maintains product quality across custom and standardized furniture components. Additionally, DriveWorks can be configured to ensure that furniture designs automatically comply with relevant regulatory safety standards across different markets. This reduces the risk of non-compliance and streamlines the process of adapting to changing regulations.

Online sales

Customer preference for making furniture purchases online requires an effective digital sales strategy with a user-friendly online sales platform. The growing demand for customized furniture presents a challenge for furniture manufacturers to enable customers to self-serve customized options.

How DriveWorks helps

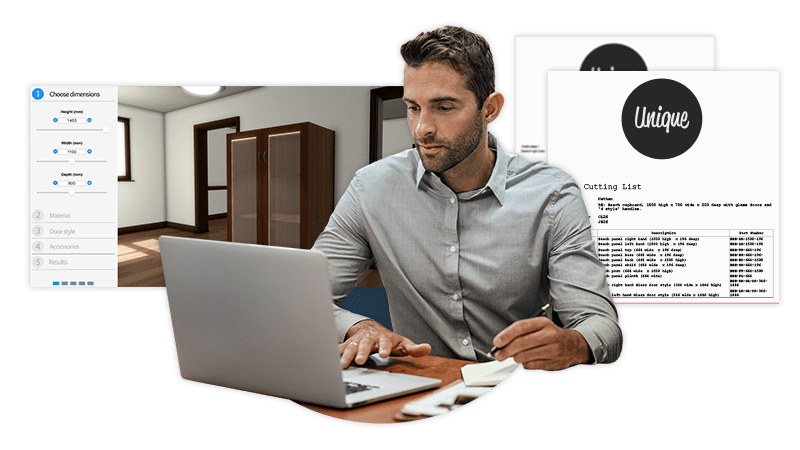

DriveWorks 3D product configurators help visually communicate customized furniture features to customers. They enable customers to visualize custom options and make more informed purchases, resulting in frictionless buying experiences and improved customer satisfaction.

Market competition and consumer preferences

Competing with low-cost producers, particularly from countries with lower labor costs, puts pressure on pricing and margins. Rapidly changing consumer preferences and staying up to date with changing design trends put additional pressure on design engineers to keep pace with new product designs.

How DriveWorks helps

DriveWorks enables furniture manufacturers to optimize pricing strategies by factoring in real-time material costs, labor, and other variables. This ensures that pricing remains competitive while maintaining profitability. Furniture design engineers are freed up to work on new product innovation because DriveWorks design automation technology handles the majority of the “same but different” design work.

DriveWorks furniture manufacturer customer success story

Dolphin Solutions design and supply a range of products and accessories for commercial washrooms. They cut their sales process down from days and weeks to minutes and hours with the implementation of DriveWorks design automation and CPQ for Manufacturing technology.

The days and weeks are cut down to minutes and hours, because our customers are finding their final design much quicker. They can see all their options and the drawings are generated automatically.”

Robert Allen, Product Design Engineer at Dolphin Solutions

Featured blog

DriveWorks is used by manufacturing companies from a range of industries.

Because DriveWorks is modular, scalable, and incredibly versatile, our customers use DriveWorks in many different ways, building design automation, product configurator, and CPQ solutions to suit their needs.

In our recent blog How Different Industries Use DriveWorks we took a deep dive into a selection of some of the many different industries where DriveWorks technology is enabling businesses to overcome their industry challenges.