The materials handling industry, and in particular conveyor manufacturers, is integral to numerous sectors, from manufacturing and warehousing to distribution and logistics. However, the industry faces several challenges that can impact efficiency and productivity. DriveWorks technology provides a powerful solution to these challenges by automating the design process, reducing lead times, enhancing cost efficiency, ensuring accuracy and quality, and providing scalability for growth. Conveyor manufacturers are using DriveWorks design automation and CPQ sales configurator software to streamline manufacturing and sales processes, and enhance efficiency and business performance.

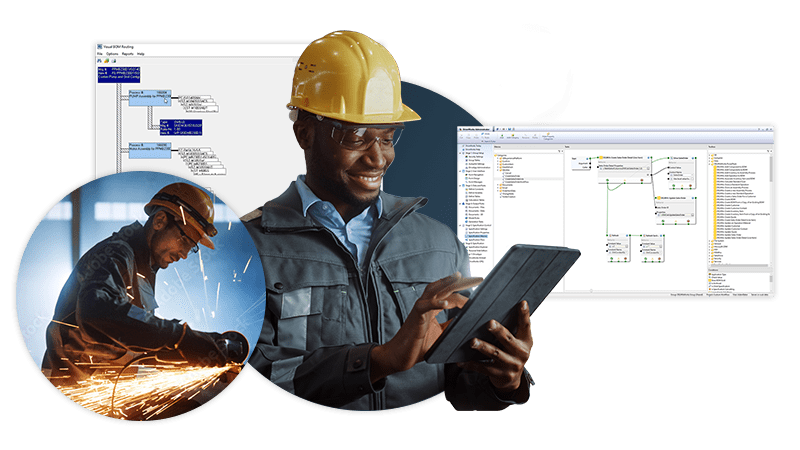

Complex production processes for Conveyor Manufacturers

Manufacturing conveyor systems involves intricate processes, especially with advanced technologies such as automation. Efficiently managing these complex production processes is a significant challenge.

How DriveWorks helps

DriveWorks automates the design and engineering processes, simplifying production complexities. Manufacturers can create rules and logic to drive the design process, ensuring consistency and efficiency across various conveyor system configurations.

Quality Control for Conveyor Manufacturers

Ensuring high quality and reliability in conveyor systems is crucial. Balancing cost-effective production while maintaining stringent quality standards is an ongoing challenge for manufacturers.

How DriveWorks helps

DriveWorks enforces design standards and quality controls through automation. Consistent application of rules and specifications minimizes errors, ensuring each conveyor system meets high-quality standards.

Supply Chain Disruptions

Conveyor manufacturers are vulnerable to supply chain disruptions, leading to production delays, increased costs, and lost sales.

How DriveWorks helps

DriveWorks enables agile design changes. In response to supply chain disruptions or material availability changes, manufacturers can quickly adapt product configurations without extensive manual reengineering, mitigating the impact of disruptions.

Customization Demands For Conveyor Manufacturers

Customers increasingly demand customized conveyor solutions to meet specific needs. Adapting equipment to different applications without significantly increasing production costs or lead times is challenging.

How DriveWorks helps

DriveWorks CPQ solutions excel in managing customization demands. Manufacturers can create configurable product models, allowing customers or sales teams to customize conveyor systems according to specific requirements while ensuring these customizations remain within predefined parameters.

Environmental Compliance

Meeting environmental regulations, such as reducing energy consumption and waste, adds complexity to the conveyor manufacturing process and may require additional reporting.

How DriveWorks helps

DriveWorks incorporates environmental considerations into the design process, optimizing material usage and ensuring designs comply with environmental standards and regulations. This helps manufacturers achieve sustainability goals in their production processes.

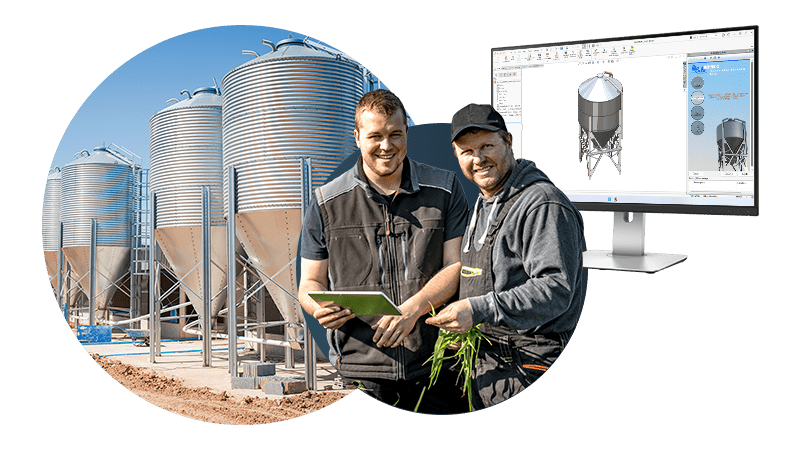

Managing Customer Expectations

Communicating the customized features and functionality of complex conveyor solutions is challenging. Customers need a clear understanding of product options and variants to make informed decisions.

How DriveWorks helps

DriveWorks 3D visual configurators effectively communicate complex product features to customers. They allow manufacturers to quickly adapt to changing customer expectations by integrating new features and technologies into customized conveyor configurations, essential for meeting evolving customer demands.

DriveWorks Customer Case Study: Engineering time reduced to under 15 minutes

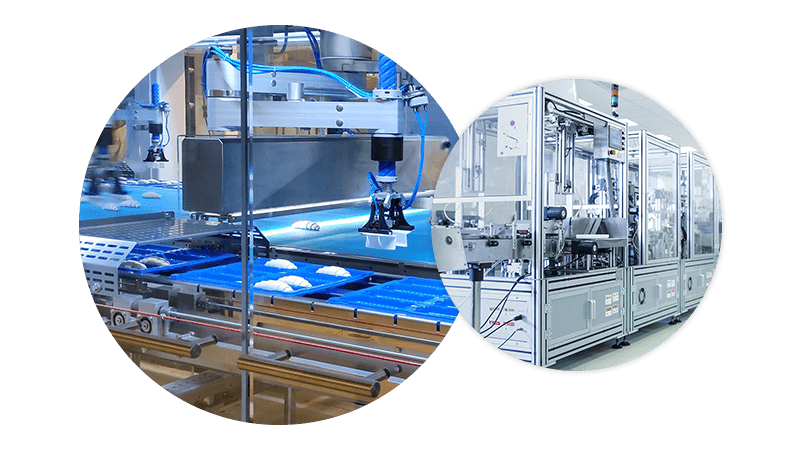

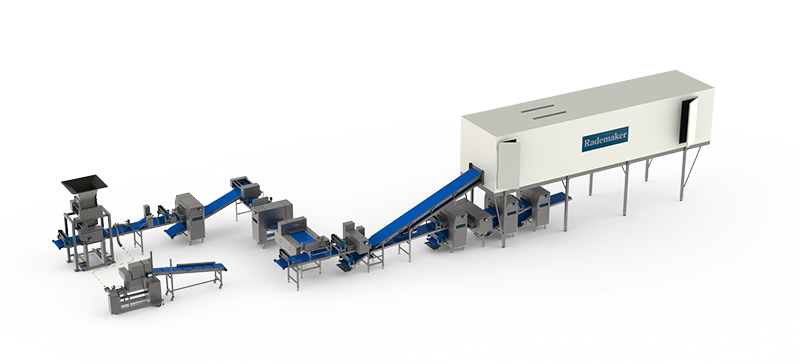

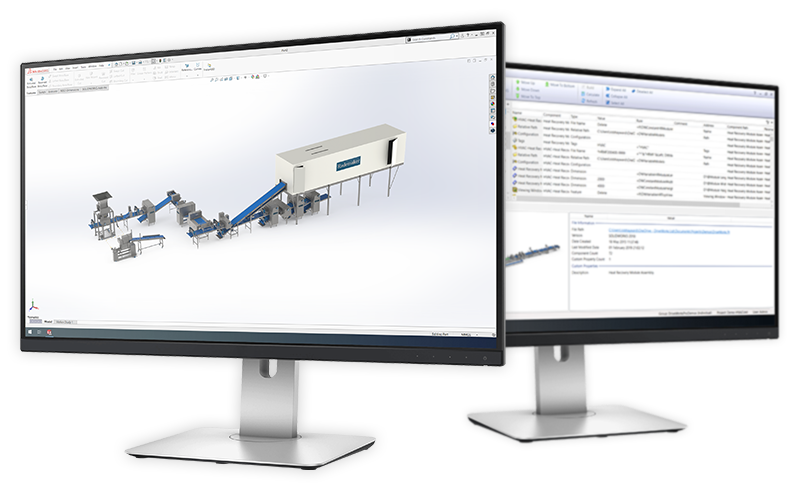

Rademaker have over 40 years of experience providing solutions for the food processing industry. Their broad portfolio of production lines includes bread, laminated dough, croissants, pastry, pies and pizza.

Before implementing DriveWorks the engineering time required to prepare an order for manufacturing was substantial and Rademaker identified the need for a product configurator and SOLIDWORKS automation solution to optimize their engineering processes.

They wanted the ability to fill out the specification of a machine and have the 3D models, drawings and BOMs automatically generated.

Using DriveWorks technology they now automatically update their SOLIDWORKS parts, assemblies and create production-ready engineering drawings. This removes repetitive tasks from the engineering team, freeing valuable resource to other tasks.

Subsequently, Rademaker achieved their target of reducing engineering time to less than 15 minutes for modular units. They also achieved a 30% reduction in time during the standardization process as DriveWorks enabled them to optimize their product structure work flow.

Featured Blog

DriveWorks is used by manufacturing companies from a range of industries.

Because DriveWorks is modular, scalable, and incredibly versatile, our customers use DriveWorks in many different ways, building design automation, product configurator, and CPQ solutions to suit their needs.

In our recent blog How Different Industries Use DriveWorks we took a deep dive into four of the many different industries where DriveWorks technology is enabling businesses to overcome their industry challenges.