Production efficiency is a key challenge for many businesses and plays a key role in remaining competitive. Europe is falling behind in productivity compared to the US, and slower adoption of technology associated with production efficiency and innovation could be part of the issue. Integrating design automation into your design process enables your teams to work smarter, and your business to be more flexible and efficient. Regardless of the size of your business or the sector that you work in, design automation can improve productivity, foster innovation, and give you a significant competitive advantage.

Speed up your workflows

One of the biggest benefits of design automation is the ability to dramatically reduce the amount of time spent on repetitive design tasks. Traditional design processes, especially for custom products, can be incredibly time-consuming and labor-intensive.

Automation of custom product design streamlines the workflow for “same but different” products and reduces the need for manual interventions. By automating repetitive design tasks, design engineers are freed up to spend more time on new product development and innovation.

Design automation, combined with a CPQ solution, enables sales teams and customers to configure custom products from a pre-set menu of options and automatically receive accurate pricing and quotes. This can be particularly valuable for businesses selling through a reseller or trade network, making it easier for them to quote and sell your products. Quicker quotes and sales cycles make your business more competitive and win more custom product sales.

Consistency & accuracy

Maintaining consistency and accuracy is essential when creating custom designs at scale, especially when selling through remote channels. Automation enables custom products to be consistently produced with guaranteed quality standards. Design rules and parameters are built into the automation process to ensure that products meet all requirements. This means custom product designs are manufacturable and meet quality standards and industry regulations.

This is particularly relevant for businesses that sell in different countries or sectors where regulations and requirements may vary. Being able to guarantee that products are consistently high quality and conform to relevant requirements gives resellers confidence to reliably sell your products.

Scalability

Scalability is key as demand for custom products continues to increase and businesses need to remain competitive. Manual design processes are unable to handle the same volume of custom product designs efficiently. The automation of repetitive tasks associated with custom design enables businesses to easily scale up their operations without the need for additional headcount.

Superior customization

With customer expectations of custom products continuing to increase, businesses need to find ways of profitably meeting this demand. Using design automation tools, manufacturers automatically generate the 3D models and manufacturing data and drawings required to sell and produce the finished customized product.

The ability to provide a range of customization options makes your product more attractive to buyers and improves customer satisfaction.

Cost efficiency

While there is an initial investment for some design automation tools, the long-term cost savings are substantial. Reduced costs, minimized errors, and faster project completion times can all contribute to financial savings. Additionally, design costs are lower due to fewer man-hours, enabling competitive product pricing.

Design automation reduces bottlenecks and mistakes, so you can deliver custom products to your customers quickly. This improves customer satisfaction levels and increases the likelihood of repeat purchases.

Staying ahead of the competition with DriveWorks design automation technology

F.H.Brundle wanted a solution that would allow internal teams, customers, and distributors to configure balustrade systems to their own dimensions online, then automatically receive order-specific quotes and technical drawings in minutes. Estimating and quoting custom designs was time-consuming and vulnerable to errors.

They identified an opportunity to improve the experience of internal teams and trade customers by creating a product configurator.

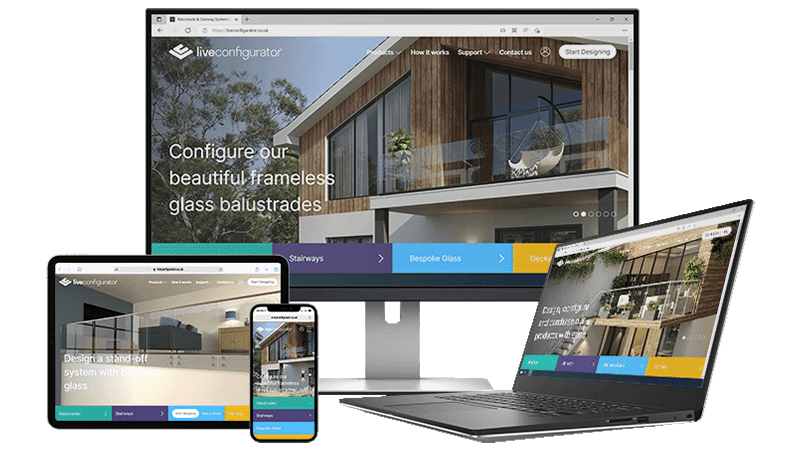

F.H. Brundle chose DriveWorks Pro as their design automation and online product configurator solution. Using DriveWorks, F.H. Brundle built Liveconfigurator™, an online 3D product configurator for their internal teams, distributors and customers.

With many years of experience in both the practical and technical design of balustrades, they have added their knowledge and expertise into their configurator, to make it easy for anyone to design a system that meets their needs.

“Our sales staff are saving valuable time and our customer service is better than ever. We are building customer loyalty, increasing sales, and avoiding mistakes.”

Richard Twiddy, Design Office Manager, F.H.Brundle

Design automation blog series