In the architectural and building components industry, customization, efficiency, and quality are key components of success. Manufacturers face the challenge of balancing these factors while staying competitive and following strict regulations.

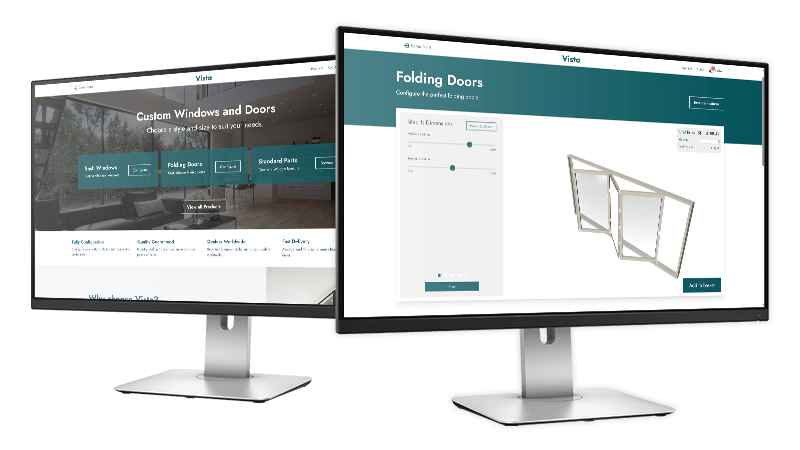

Here’s how DriveWorks design automation, 3D product configurator, and CPQ technology is being used by many businesses in the architectural & building components industry to overcome those challenges.

Customization and Variability

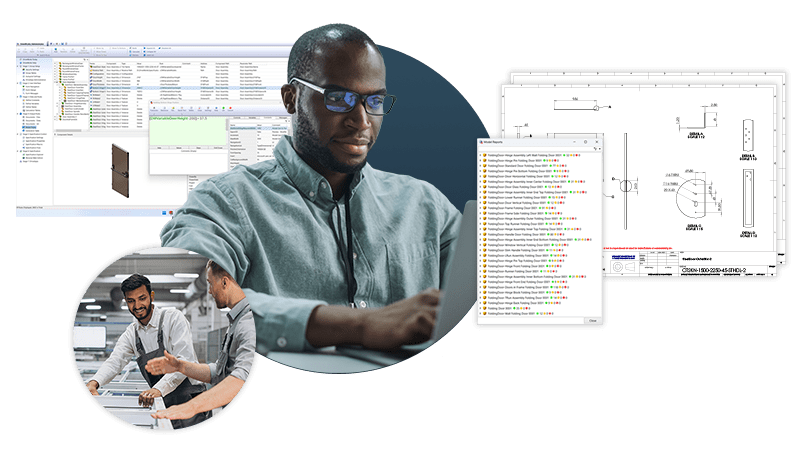

Architectural and building components often need to be highly customizable to meet the specific design requirements of different projects. This customization can lead to production inefficiencies, as each order may be unique, requiring significant time and effort to design.

How DriveWorks Helps

DriveWorks CPQ enables architectural and building component manufacturers to create configurable design templates.

Engineers can define rules and parameters that guide the customization process based on customer requirements. This ensures that each order, even if highly customized, follows a standardized and automated design process.

As a result, production efficiency is improved by reducing the time and effort required for unique designs.

Material Costs and Availability

Fluctuations in the cost and availability of raw materials can significantly impact production costs, profit margins, and design accuracy. This is often the case for manufacturers of architectural & building components.

How DriveWorks Helps

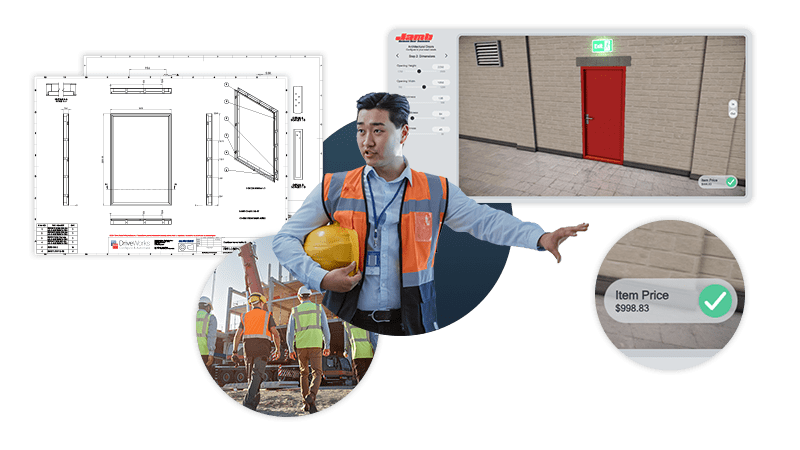

DriveWorks integrates with real-time data sources to monitor material costs and availability. By automating the quotation process, DriveWorks accurately adjusst pricing based on fluctuations in material costs, ensuring accurate and competitive pricing.

This dynamic pricing model helps maintain profit margins and adapt to changing market conditions.

Quality Control

Maintaining consistent quality across both custom and standardized components is crucial. Ensuring that products meet industry standards and customer expectations requires robust quality control measures.

How DriveWorks Helps

DriveWorks ensures consistency in design by using standardized rules and parameters. Additionally, DriveWorks can embed quality control checks within the design automation process, reducing the risk of errors and ensuring that products meet both industry standards and customer expectations.

Regulatory Compliance

The architectural and building components industry is subject to a wide range of different building codes and regulations. Ensuring that products comply with these standards can be complex and may vary across regions.

How DriveWorks helps

DriveWorks enables manufacturers to embed regulatory requirements into the design rules. This ensures that each product generated through the automation process complies with relevant building codes and regulations. By automating compliance in this way, DriveWorks helps architectural & building components manufacturers avoid costly errors and ensures that all products meet the necessary legal standards.

Long Sales Cycles

The sales cycle in the architectural and building components industry can be lengthy, especially for large-scale projects, delaying project timelines and impacting revenue flow.

How DriveWorks helps

DriveWorks CPQ solution accelerates the sales cycle by providing a quick and accurate way to generate quotes and designs. With the automation of design and quoting processes, manufacturers can respond quickly to customer inquiries, reducing the time it takes to finalize orders. This efficiency significantly shortens the overall sales cycle, particularly beneficial for large-scale projects where time is a critical factor.

Competitive Pricing

The architectural and building components industry is highly competitive, with multiple manufacturers offering similar products. Maintaining competitive pricing while ensuring quality can be challenging.

How DriveWorks helps

DriveWorks enables manufacturers to optimize pricing strategies by factoring in real-time material costs, labor, and other variables. This ensures that the pricing remains competitive while maintaining profitability. By leveraging real-time data and automation, manufacturers can stay ahead of the competition without sacrificing quality or margins.

How Our Customers in the Architectural and Building Components Industry are Using DriveWorks

ERHARDT manufactures high-quality, customized products for sun protection, outdoor living, and terrace roofs.

Using DriveWorks technology to connect sales and manufacturing has enabled ERHARDT to improve customer experience, streamline the sales process, reduce errors, and optimize engineering and manufacturing processes.

The accuracy and reliability of DriveWorks Design Automation for SOLIDWORKS has enabled ERHARDT to manufacture the products configured by the retailer without further modification by the design department. I

Implementing DriveWorks Design Automation and CPQ for Manufacturing has enabled ERHARDT to keep pace with increasing demand while maintaining its reputation for high-quality products.

markilux GmbH & Co. KG is an award-winning awning company, based in Germany.

Prior to the introduction of DriveWorks, products had to be customized by hand. Each assembly had to be manually opened and edited, the drawing derived and saved. A large, time-consuming effort with an incalculable potential for errors.

Using DriveWorks Pro, markilux have reduced design time from 4 hours to 20 minutes.