With Digital Transformation businesses are working smarter. Technology, software and automation are allowing companies to focus on future opportunities and innovation.

Technology is increasing efficiency, improving accuracy, streamlining business to consumer relations, boosting speed, and allowing for a wider range of products.

Digitalisation doesn’t always look the same. It can be different depending on industry and organisation.

For some, the aim may be to simply automate lengthy manual processes. Jobs that previously took hours, days or even weeks to accomplish can now be achieved within minutes.

While for others, the goal is to create a smart factory. Transforming entire factories so they become digital and connected, with machines that can improve processes through automation and self-optimization.

A-LINE

The European Software and Services Initiative, NESSI report that Industry 4.0 will rely on technologies to develop intelligent cooperative systems with increased data sharing and analytics capabilities.

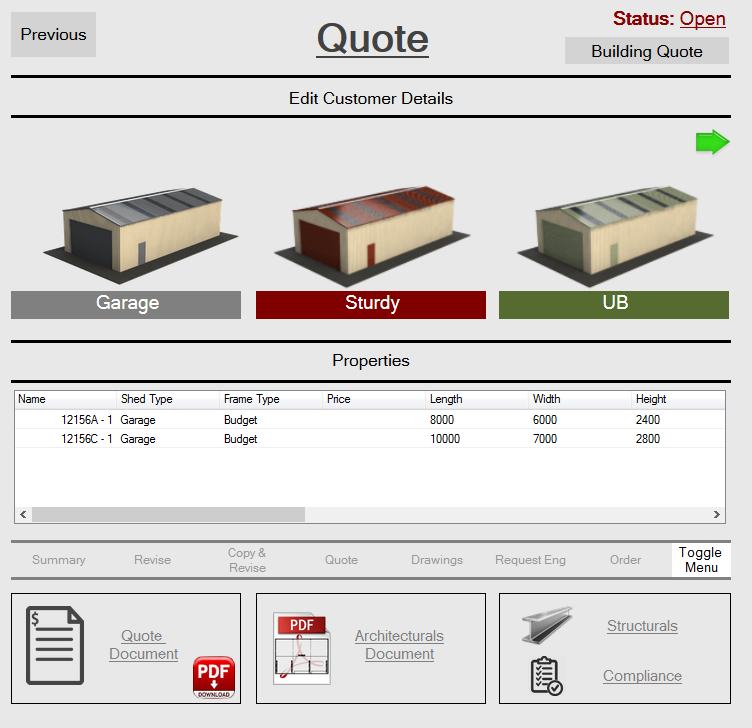

Using DriveWorks software enabled A-LINE to create up to 200 designs per day, giving them a huge competitive advantage in the marketplace.

The system they’ve built in DriveWorks provides an easy to use homepage for their sales team, which provides instant quotes and drawings for the customer.

It also has a quote management area to help the sales team manage their quotes in one place, quickly and easily.

By replacing a time consuming manual quoting processs with automation, A-Line saved time, saved money and reduced errors, without compromising on quality or professionalism.

With the introduction of software, the way manufacturing businesses operate is changing for the better. Software is freeing up time and resources allowing manufacturers to continue innovating and moving forward.

Rademaker

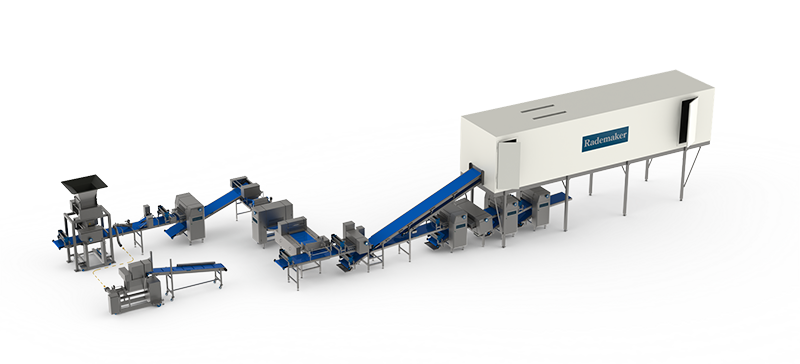

Rademaker, a company providing solutions for the food processing industry found that with the use of DriveWorks, they reduced engineering time to less than 15 minutes.

With a new Zero Effort Engineering process, the engineer only needs to fill in the specifications of a machine and the 3D models, drawings and bill of materials are automatically generated.

This reduction in engineering time not only helped to achieve targets but also increased flexibility, variants, functionality and the number of options they can handle.

Shotton Group

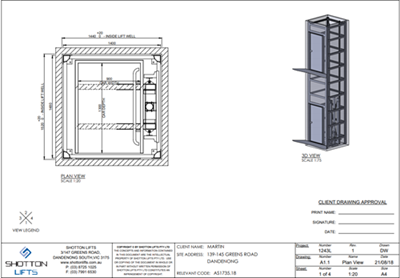

Through the introduction of software and automation, the Shotton Group cut the process of creating product sales documentation from half a day down to 30 minutes.

Engineers’ time previously spent on repetitive tasks can now be used on more valuable tasks such as R&D.

For the Shotton Group, the integration of software has saved them time, improved customer satisfaction and taken them a step close to achieving objectives.

F.H.Brundle

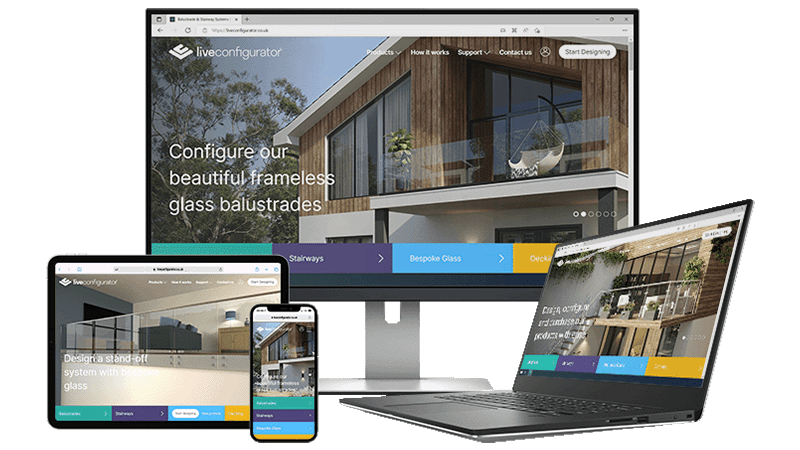

DriveWorks customer, F.H.Brundle are a wholesaler of steel products, stocking over 8,500 products. As they are adding new products all the time, it was important for them to find a solution that could be set up and managed by themselves.

Using DriveWorks, F.H.Brundle created their own online configurator for internal teams, distributors and customers.

Since the introduction of software, F.H.Brundle’s businesses processes now allow customers to configure systems to their own dimensions, creating accurate quotes and detailed drawings in minutes. Saving their customers hours of work and helping to eliminate mistakes.

The Entrepreneur Europe agrees that done right, a digital shift can lead to increased savings, happier customers and better prospects in both the short and long term.

Aline

“Using DriveWorks enabled us to create up to 200 designs per day”

– Craig Barker, Director, A-LINE

Rademaker

“Order-engineering has gone from 2 hours to 15 minutes.”

– Rob Beffers, Manager Integrated Process Control, Rademaker BV

FH Brundle

“Customers can get a quote anytime they want it, 24/7/365.”

– Richard Twiddy, Design Office Manager, F.H.Brundle

Shotton Group

“We’ve reduced the amount of time taken to complete forms from half a day to only 30 minutes.”

– Martin Clenick, Engineering Manager, Shotton Group

Laing O’Rourke

“DriveWorks has allowed us to automate the routine processes that we undertake day in and day out.”

– Dr Scott McGovern, Digital Engineering Lead, Laing O’Rourke

BKW

“We now have more time to focus on our workflow and business analytics ”

– Adam Baker, Operations and IT Manager, BKW Instruments