DriveWorks World is our annual value-added technical event for DriveWorks users.

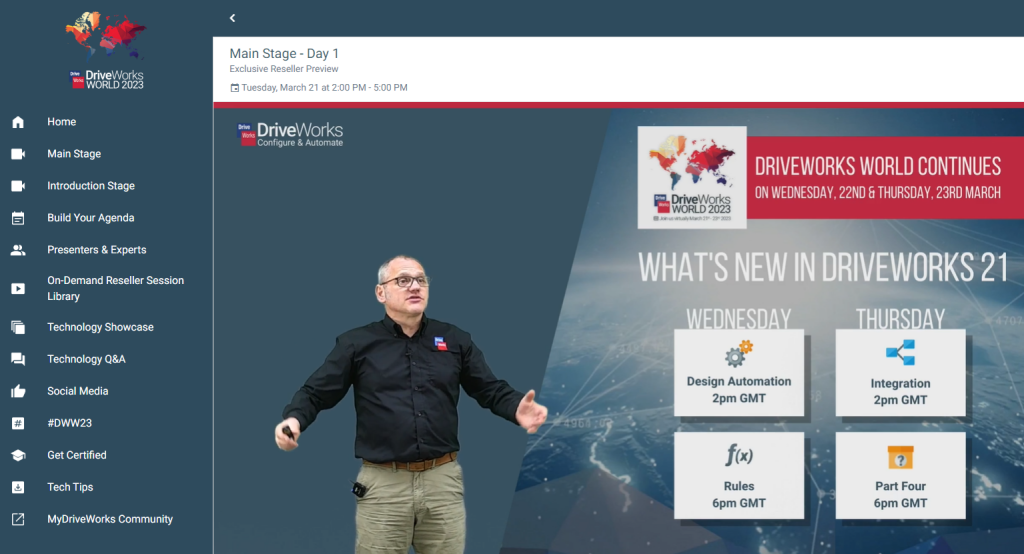

Wednesday was the official start of DriveWorks World 2023 technical learning, bringing everyone together virtually.

This year DriveWorks World is held over three days.

Here’s what happened on day two.

Welcome and Introduction

The day kicked off with a warm welcome to DriveWorks World from Maria Sarkar, VP & Co-Founder, explaining why we host our annual technical knowledge and networking event. Glen Smith, DriveWorks CEO then joined to tell us about the What’s New in DriveWorks 21 sessions happening throughout the event.

We began with a tour of the event app to highlight all of the ways we’ve made learning and networking easier than ever this year for the event.

A lot has changed over the past few years at DriveWorks HQ, so we thought it only right to take you all on a tour of our office buildings. This included a first look at our new offices and dedicated training room. Of course, we couldn’t film a tour of our HQ without featuring our Resident Feel Good Officer, Ruby, the Labrador.

Implementation

In the first technical session of the day, we talked about implementation. Our Technical Engagement Manager, Oliver, introduced our DriveWorks Experts – Ian, Dave, Phil, and Paul for a technical panel discussion. They shared their top tips for getting started with your implementation, how to plan your projects and our team’s favorite hidden gems.

Our experts mentioned how taking a step back and looking at your project and evaluating what you want to do on a larger scale can make it easier to begin and manage further down the line. DriveWorks is exciting and fun so when starting with our software or a new project, it can work well to play around with the software in a sandbox. It can be a place to try out new things, which you can learn from and then carry on to your actual projects.

Automating CAD

We began with an overview of Automating CAD. Our Technical Specialist, Will, explained how Automating CAD is at the core of DriveWorks technology.

This was then followed by a project run-through. We were taken through a project that is available inside our Tech Tips library, modified by Senior Applications Engineer, Ollie.

Ollie and Will were then joined by Dave for an expert discussion on the topic. They talked about how DriveWorks is modular, so it is easy to start off small and then add other child projects to build a project and scale. They answered questions from the audience.

Workflow

Oliver joined us back in the studio again to host a Workflow overview and project run-through with Technical Manager, Dave. Dave took us through a specification flow, highlighting how users can benefit from using DriveWorks to create these within projects. Workflow is a core technology of DriveWorks. It gives you complete control over Who, What, and When in your DriveWorks configurator.

Oliver and Dave were then joined by Senior System Developer, Thomas, to talk about triggering tasks within workflows. They hosted an expert panel to answer questions from our attendees which even featured an on-the-spot live demo.

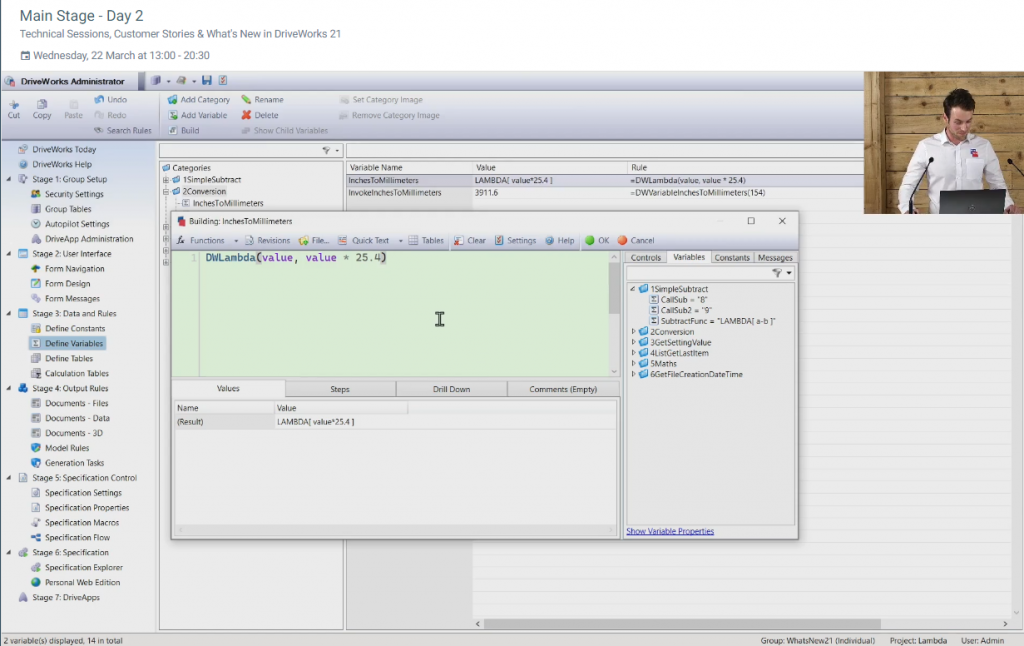

Rules

Will, along with our Systems Team Manager, Jake, took us through a project run through about Rules. Everything in DriveWorks is based on rules, they are the foundations of all DriveWorks projects. Jake took us through the DriveWorks rule builder.

We then followed this sessions with an expert panel session with more questions from the audience and another live demo by Jake.

What’s New

Of course, it wouldn’t be a DriveWorks World without DriveWorks CEO, Glen Smith announcing What’s New in the latest release of DriveWorks.

Broadcast on the live stream, Glen shared parts one and two of all the exciting new additions and functionality added to DriveWorks 21.

In part one, Glen shared what’s new with Design Automation and in part two Glen shared the latest additions to Rules.

It was great to see so many people getting involved within the chat, sharing what new features they’re most excited about and how they will use them.

We’ve got another two parts of the what’s new happening on Thursday, 23rd. Make sure to join us at 2pm and 6pm GMT to hear Glen sharing more of What’s New in DriveWorks 21.

Hearing from DriveWorks Customers

A variety of DriveWorks users from companies across the world, in a wide range of industries, then took to the stage to tell us about the many different ways they all use DriveWorks.

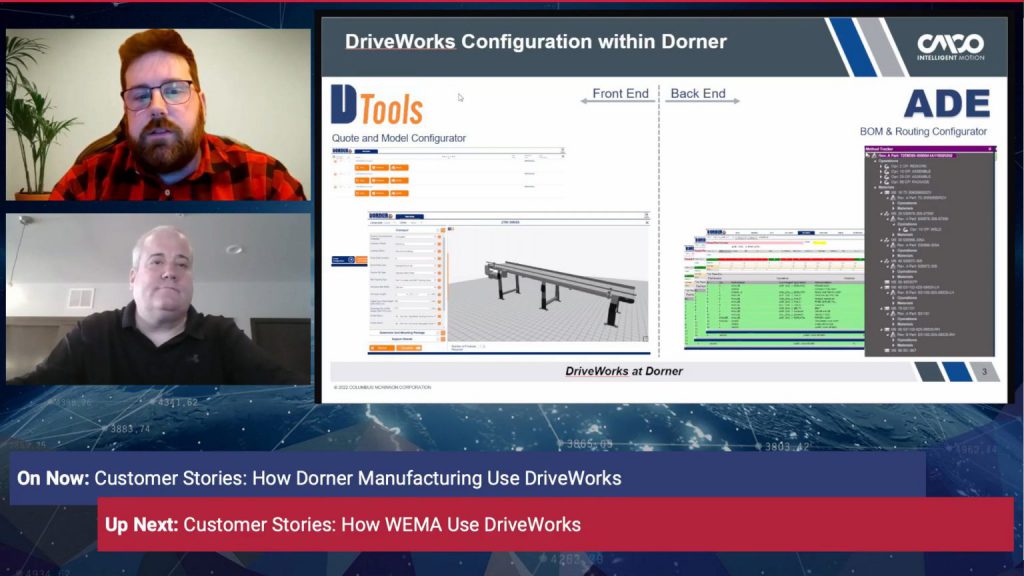

Dorner Manufacturing

Trading all over the world including in the U.S., Asia & Europe, Dorner Manufacturing specializes in built-to-order conveyors.

They explained how the ease of DriveWorks has allowed them to create their own front-end sales configurator, DTools.

They showed us how they updated this configurator and their plans for the future.

We also saw how Dorner have integrated DriveWorks with their ERP system.

Throughout the presentation, the team at Dorner shared their top tips, which were gratefully received by attendees!

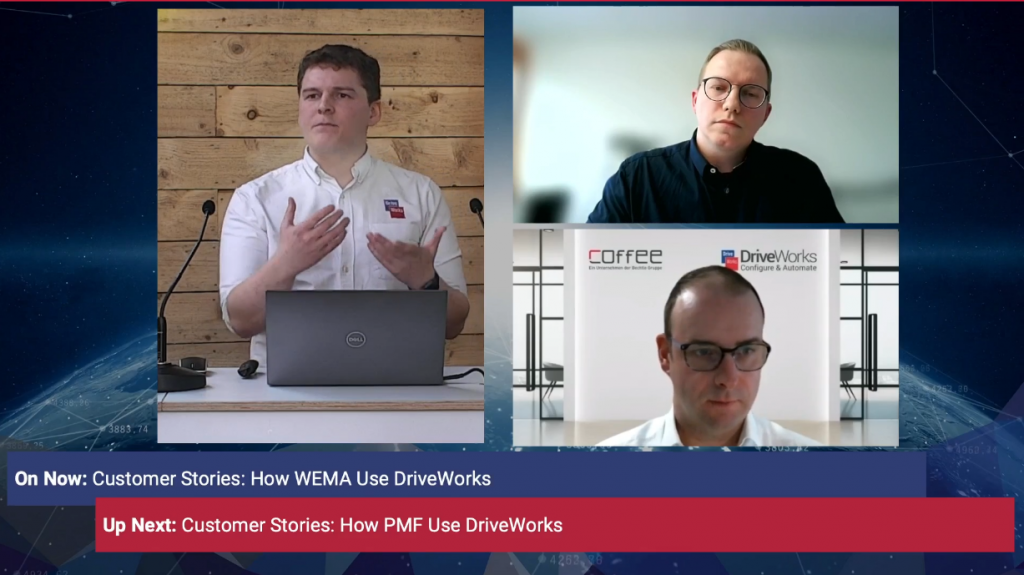

WEMA

WEMA GmbH, based in Germany, manufactures electrical resistance heaters and insulation for industrial applications, as well as systems parts for moulds for the plastic processing industry.

For this presentation, Tobias Grebe- DriveWorks Product Manager at DriveWorks reseller, Coffee GmbH joined us to introduce WEMA.

Steven Bracke, Head of Virtual Construction at WEMA GmbH at WEMA showed us how they use DriveWorks to create their sales configurator. It has allowed them to minimize their error rate during the design and manufacturing process. Steven also talked about the support they have received from Tobias and the Coffee team.

PMF-System

PMF solutions are a manufacturer of customized industrial solutions based in Switzerland. Before DriveWorks, PMF was receiving several requests for similar products. They wanted an online configuration solution to reduce repetitive sales work and to keep up with online shopping trends.

They decided DriveWorks was the correct solution for them because it is directly connected to SOLIDWORKS, they wanted instant 3D previews and because of how easy it is to use. They have taken a scalable approach to build their DriveWorks projects, starting small and building up over time. This approach has seen them move quickly with their DriveWorks projects and reap the benefits immediately.

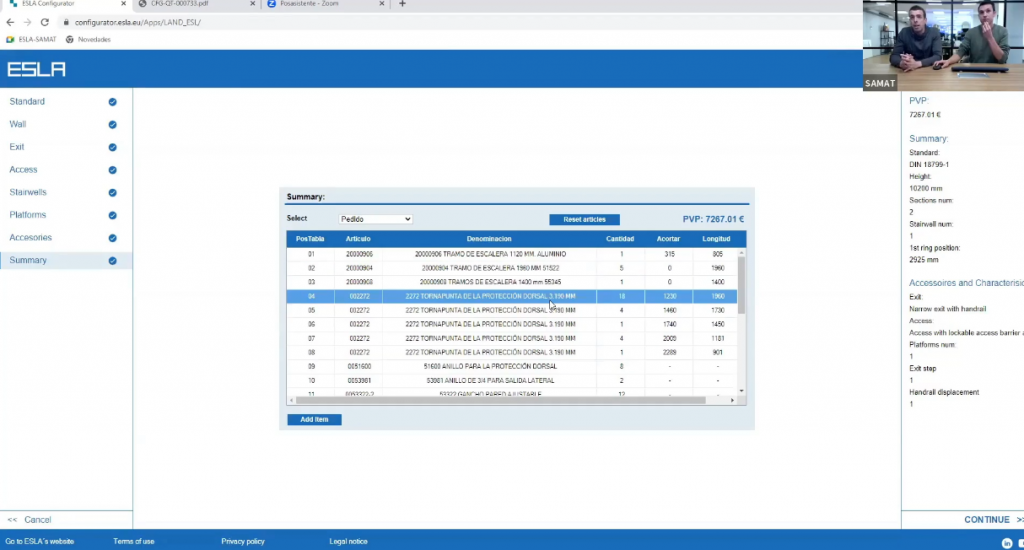

ESLA

For this presentation, we were joined by one of our Authorized DriveWorks Services Partners, Ingenieria SAMAT. They told us about how they have been working with ESLA to help them set up their DriveWorks implementation.

ESLA is a manufacturer of ladders, work platforms, and mobile scaffoldings in Spain.

They have used DriveWorks to create a configurator which has meant that all their processes are controlled, and errors are reduced.

Using DriveWorks, they have been able to raise the percentage of accepted quotations and streamlined their manufacturing process. They have focused on creating a great user experience and used DriveWorks 3D features to make it easy for anyone to configure custom ESLA products.

F. H. Brundle

Just before DriveWorks World, some of our team headed down the motorway to visit F.H.Brundle. They are UK-based wholesalers of steel products which include a market-leading range of handrail and balustrade systems.

Our team recorded an interview with some of the F.H. Brundle team and we played this during the DriveWorks World livestream. They explained they wanted a solution that would allow internal teams, customers, and distributors to configure balustrade systems to their own dimensions online, then automatically receive order-specific quotes and technical drawings in minutes.

Liveconfigurator™ is F.H.Brundle’s online 3D configurator which provides quotes and full technical drawings for custom orders.

ESLA

For this presentation, we were joined by one of our Authorized DriveWorks Services Partners, Ingenieria SAMAT. They told us about how they have been working with ESLA to help them set up their DriveWorks implementation.

ESLA is a manufacturer of ladders, work platforms, and mobile scaffoldings in Spain.

They have used DriveWorks to create a configurator which has meant that all their processes are controlled, and errors are reduced.

Using DriveWorks, they have been able to raise the percentage of accepted quotations and streamlined their manufacturing process. They have focused on creating a great user experience and used DriveWorks 3D features to make it easy for anyone to configure custom ESLA products.

On-Demand Sessions

Alongside the live broadcast, this year there are also over 100 on-demand technical learning sessions.

These sessions cover a variety of DriveWorks topics, at different skill levels. You don’t need to watch them all, you can select the sessions that are relevant to you and your learning.

These on-demand sessions will be available throughout the rest of the event, so you can watch them even when we’re not broadcasting live. They will also remain available after the event so you don’t need to rush through them.

There are reseller-specific on-demand sessions as well as technical on-demand sessions for everyone to learn more about DriveWorks software.

Join Us for Day 3

DriveWorks World continues on Thursday, 23rd March – it’s not too late to join us.