DriveWorks software is used by companies from a range of industries, helping them increase sales, streamline processes, and achieve their business goals. DriveWorks is modular, scalable, and incredibly versatile so our customers use DriveWorks in many different ways, building their own design automation and CPQ solutions to suit their company needs.

That’s why sharing customer stories is an important part of DriveWorks World. It enables you to see how other companies have adopted our technology across a range of different industries.

The customer stories we share are designed to enable you to learn how other DriveWorks users have built their implementation, the functionality they have used, the processes they have followed, how they maintain it and their plans for the future. It’s the ideal way to pick up tips, tricks and inspiration for your own implementation.

Don’t miss the customer presentations at DriveWorks World 2024, register now to join us!

Below is a summary of the customers we heard from at DriveWorks World 2023

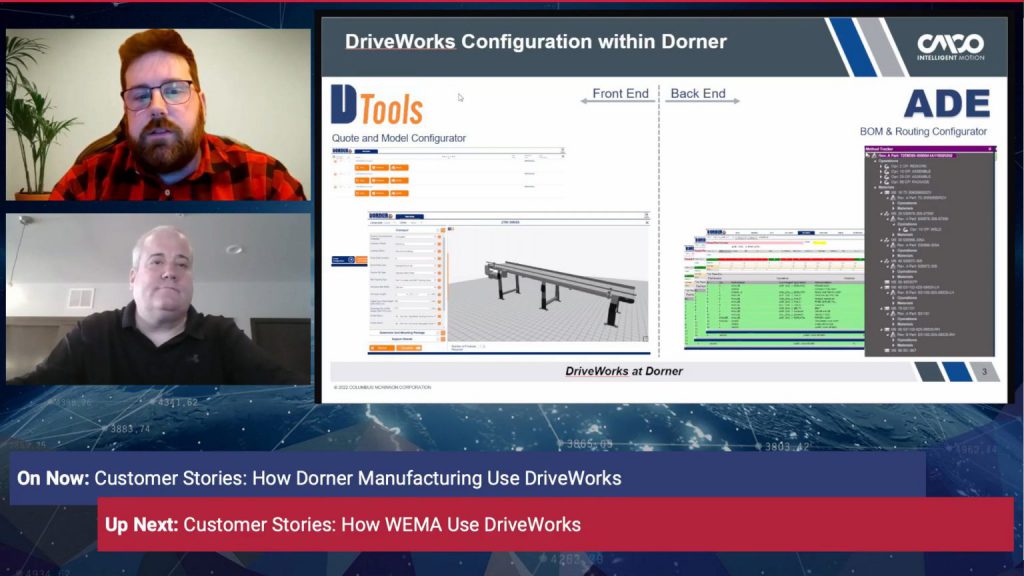

Dorner Manufacturing

Trading all over the world including in the US, Asia and Europe, Dorner Manufacturing specializes in built-to-order conveyors.

Dorner presented DTools, the front-end sales configurator they have built using DriveWorks. Dorner’s team talked about the process of creating their configurator and the ease of using DriveWorks to create it.

They showed us how they updated this configurator and their plans for the future. We also saw how Dorner has integrated DriveWorks with their ERP system. Throughout the presentation, the team at Dorner shared their top tips, which were gratefully received by attendees.

WEMA

WEMA GmbH, based in Germany, manufactures electrical resistance heaters and insulation for industrial applications, as well as system parts for moulds for the plastic processing industry.

For this presentation, Tobias Grebe, DriveWorks Product Manager at DriveWorks reseller, Coffee GmbH joined us to introduce WEMA.

Steven Bracke, Head of Virtual Construction at WEMA GmbH at WEMA showed us how they created their sales configurator using DriveWorks. It has allowed them to minimize their error rate during the design and manufacturing processes. Steven also talked about the support they have received from Tobias and the team at Coffee.

PMF-System

PMF solutions are a manufacturer of customized industrial solutions based in Switzerland. Before DriveWorks, PMF was receiving several requests for similar products. They wanted an online configuration solution to reduce repetitive sales work and to keep up with online shopping trends.

They decided DriveWorks was the correct solution for them because they already used SOLIDWORKS, they wanted instant 3D previews and because of how easy it is to use. They have taken a scalable approach to build their DriveWorks projects, starting small and building up over time. This approach has seen them move quickly with their DriveWorks projects and reap the benefits immediately.

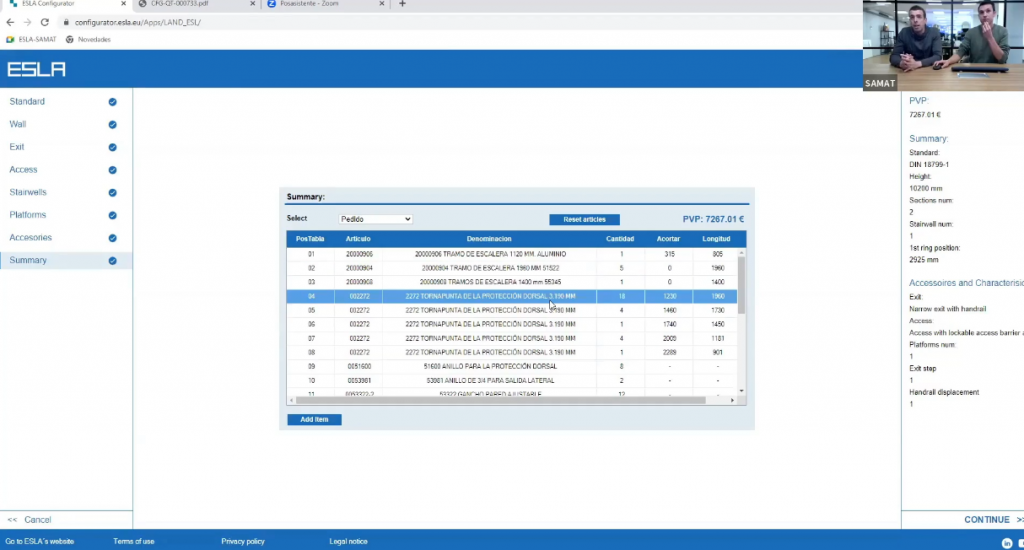

ESLA

For this presentation, we were joined by one of our Authorized DriveWorks Services Partners, Ingenieria SAMAT. They told us about how they have been helping ESLA set up their DriveWorks implementation.

ESLA is a manufacturer of ladders, work platforms, and mobile scaffoldings in Spain.

They have used DriveWorks to create a configurator which has meant that all their processes are controlled, and errors are reduced.

Using DriveWorks, they have been able to raise the percentage of accepted quotations and streamlined their manufacturing process. They have focused on creating a great user experience and used DriveWorks 3D features to make it easy for anyone to configure custom ESLA products.

F. H. Brundle

Just before DriveWorks World, some of our team headed down the motorway to visit F.H.Brundle. They are UK-based wholesalers of steel products which include a market-leading range of handrail and balustrade systems.

Our team recorded an interview with some of the F.H. Brundle team and we played this during the DriveWorks World livestream. F.H.Brundle explained they wanted a solution that would allow internal teams, customers, and distributors to configure balustrade systems to their own dimensions online, then automatically receive order-specific quotes and technical drawings in minutes.

Liveconfigurator™ is F.H.Brundle’s online 3D configurator which provides quotes and full technical drawings for each custom order.

Bruno Independent Living Aids

Bruno Independent Living Aids is a family-owned company based in the US, that specializes in producing products that help people to live more independently, including stair lifts, scooter lifts, and platforms.

Bruno Independent Living Aids currently has 5 main DriveWorks projects that they are successfully using to save time during their design process.

They have integrated DriveWorks with their ERP system so they can communicate better between teams and eliminate errors.

Bruno have also had great feedback from customers about their new drawings that are generated using DriveWorks.

Extronics

UK based Extronics specialize in developing and manufacturing equipment for use in hazardous areas. They serve customers all over the world in a range of industries such as oil & gas, chemical, pharmaceutical, and mining.

Nick Saunders, Operations Director, explained how the company are using DriveWorks technology to improve their business processes. He shared how they began using DriveWorks to automate CAD as a first win, before implementing a DriveWorks product configurator for Extronics’ highly configurable range of products. Nick also took us through how they have integrated DriveWorks software with their ERP and PLM systems.

Twin City Fan

Twin City Fan is an industry leading designer and manufacturer of fans, ranging from heavy-duty industrial process fans, to OEM fans. They create customizable fan solutions and have a wide range of product offerings.

Shawn Pantzke, Principle Engineer, told us about how the company are using DriveWorks and how it has benefitted them. Shawn explained some of the technical detail about how they are using hash in DriveWorks to hash the parameterization of their parts into a single string to store in their database, and how it is also integrated into their PDM add-in to get a serial number to give parts a numeric name.

Jackson Electrical Industries

Based in New Zealand, Jackson Electrical Industries are a supplier of industrial power applications and portable power solutions.

Christopher Siriphone, Project Engineer at Jackson Electrical Industries was welcomed to the event by Ahmed Lasheen, DriveWorks Technical Territory Manager for AsiaPac. Christopher shared how Jackson Electrical Industries is is using DriveWorks 3D technology on their configurable electrical boxes.

Christopher took us through a demo of their 3D product preview and how changes can be easily implemented into the design.

Tool Alliance

Based in California, Tool Alliance manufacture a range of cutting tools. Wade Anderson from SOLVESHOP and Dave Dewey from Base 10 Consultants both supported Tool Alliance through integrating DriveWorks. They were also joined by Mathieu Tapp, Director of Business Development at Tool Alliance. Their presentation explained how Tool Alliance have used DriveWorks to create ‘Speeds and Feeds Calculator’ online, using DriveWorks to solve and deploy complex solutions.

ORBIS Corporation

ORBIS Corporation is a material handling and packaging manufacturer based in the US, operating globally.

Vince Riha, Mechanical Engineer at ORBIS, took us through how the company is using DriveWorks and how they have integrated with SQL. Vince showed us how they are reading and writing data within DriveWorks and the DriveWorks tools they are using to read the database, and set the values of form controls, constants, tables, and other components.

Join Us at DriveWorks World 2024 to Hear More Customer Stories

DriveWorks World 2024 will be hosted virtually and tickets are free for all DriveWorks customers with active subscription, reseller technical staff and authorised DriveWorks partners.

We’ve built an agenda that includes lots of DriveWorks customer stories, enabling you to see real-life examples of DriveWorks technology in action across a range of industries.

DriveWorks World Customer Stories: Watch Again

All of the live customer presentations at DriveWorks World 2024 will be recorded and available to watch back in the event app so you’ll be able to catch up on any that you miss.

And if you’re in a different time zone, you can still join DriveWorks World 2024, explore all of the resources in the Event App, and watch any customer presentations you miss, at a time that works for you.

The event app for DriveWorks World 2024 will be live very soon. If you’ve already registered, we’ll send you an email with information on how to join the app. Keep an eye on your inbox!

You will need to be registered for DriveWorks World 2024 to be able to access the on-demand customer presentation recordings.