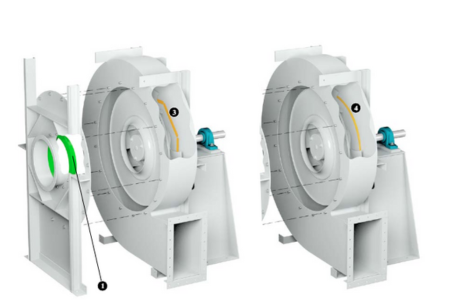

Twin City Fan, based in Plymouth, Minnesota, is an industry-leading designer and manufacturer of high-quality custom, semi-custom, and standard fans ranging from heavy-duty industrial process fans to commercial supply and exhaust fans.

Twin City Fan (TCF) needed a solution that could support both standardized and highly customized orders. By integrating DriveWorks into their process, they were able to streamline production, cut down on manual tasks, and boost efficiency across their operations.

The challenge

As a designer and manufacturer of custom, semi-custom, and standard fans, TCF operates in a competitive space, where quality and quick turnarounds are key.

In 2012, the company moved from using 2D line drawings to using SOLIDWORKS® and SOLIDWORKS PDM. Following this move, they started using DriveWorks to automate their model generation.

The solution

Using DriveWorks automation technology, TCF created a streamlined experience for both standard and custom orders. For standard orders, TCF developed a product selector tool that enables customers to input their specific requirements directly. Once the customer selects a product, the system logs the order details in a SQL database, and DriveWorks automatically generates all necessary drawings and emails the relevant information directly to the customer.

For more custom orders, drafters use an internal DriveWorks configurator to enter detailed specifications based on the customer’s requirements. Parameters such as material type, additional accessories, and paint colors can all be selected. TCF’s DriveWorks administrators are made up of engineers and drafters working in teams across multiple locations, all over the world.

Added benefits

Since integrating DriveWorks, TCF has been able to automate responses to as many as 100 customer requests per day, without the need for any manual intervention. DriveWorks has also significantly reduced the drafting team’s workload by taking over many repetitive tasks, freeing up engineers to focus on more strategic, high-value projects. Minor customizations that once took considerable time can now be completed in as little as two hours, from initial configuration to data generation and final checks. DriveWorks has also enabled TCF to streamline other internal processes, such as tracking scrap and calculating costs.

“Using the power of automation that DriveWorks gives us, we’re able to create drawings and models much faster so we can get those out to customers and to our production facilities – hence we can get products shipped out quicker. We’re not waiting on our engineering team to create custom drawings, DriveWorks will do most of the custom work for us.”

Shawn Pantzke Principal Engineer at Twin City Fan

Industry spotlight – HVAC

HVAC manufacturers are using DriveWorks design automation & sales configurator software to improve manufacturing and sales processes and be more efficient.