In a peaceful village on the outskirts of Warrington, a software company is making a big noise in the technology industry. Henry Carpenter, from Cheshire Business Magazine, catches up with the founders of DriveWorks and learns more about a local business which has a truly global reach.

From the outside, the DriveWorks headquarters don’t even hint at the hi-tech operation that’s in action behind the closed doors.

The business is set in a series of converted barns in Thelwall, a quiet village on the north eastern fringes of Warrington. It’s a tranquil spot and the handily-placed M6 is visible, but far enough away as not to ruin the peace.

To those with more than a passing knowledge of digital technology, a verbal explanation of the capabilities of DriveWorks is easy to grasp. One description is that DriveWorks is design automation and sales configurator software for companies that design and manufacture industrial products. Or, more simplistically, DriveWorks software enables companies to build their own online configurators, that automatically create all of the data to both sell and manufacture custom products.

For the layman to get an even more accurate understanding of the product which has elevated this Cheshire firm to its undoubted status as a market leader, a demonstration works better than words. Thankfully, Glen Smith, CEO of DriveWorks, is happy to oblige. Glen logs on to his laptop and opens a browser to display a contemporary looking website.

On screen is a 3D framework of a trailer, the sort we see on the back of a lorry. “We can put a couple of hinged doors on the back, or maybe a roller shutter,” explains Glen, clicking away with his mouse as the rear of the trailer is transformed before our eyes.

DriveWorks’ Co-Founders – Glen Smith and Maria Sarkar.

“Let’s change the colour to city blue,” he says, pointing the arrow to a palette on the site. “And we can easily add steel sidebars,” which he does with another simple click. The 3D model rotates, Glen zooms in and out and we get a real sense of what is being designed. All the while, there is a value figure on the bottom right of the screen, which Glen explains is the price of the trailer which changes and updates in real time according to the selections he makes.

This unique software is sold via a network of over 100 resellers across the world.

While Glen is the technical brains behind DriveWorks, Maria Sarkar, Vice President, oversees the commercial and marketing side of the operation. Maria takes obvious pride in conducting a tour around the site, making introductions to the various departments housed in several former barns, some of which are kitted to the gunnels with screens, standup desks and a mass of technological paraphernalia.

While the skill sets across the business clearly vary, there is a strong sense of family running through the whole operation; sofas, a beer fridge, games consoles. . . a sense of relaxed recreation sits alongside the intense work atmosphere at DriveWorks.

This is a firm where individual and collective responsibility is endorsed by the management. So, it’s easy to see why Maria’s mood is so bright. She – and DriveWorks – have come a long way in a relatively short space of time.

Maria’s first job was on a graduate training scheme with British Rail, before going on to work at an advertising agency in London.

“I moved to Cheshire in 1996 and set up my own sales and marketing agency,” she recalls. “One of my first clients was a SOLIDWORKS reseller. SOLIDWORKS is a market leading, 3D computer-aided design software package, with millions of users across the globe.

Glen, who had already set up a company automating production plants, joined the same reseller in 1999. He decided to write an automation programme which he wanted to take to market. He talked to me about it and that was the start of DriveWorks – we set up the company in 2001. A big early step in our development was in 2002 when we become a SOLIDWORKS Gold Partner and another important date in our timeline was in 2005 when we moved to Thelwall.”

The first few years involved working hard for a few customers. “We were pretty hand to mouth,” according to Glen – but then they secured their first customer in the form of West Midlands-based Whale Tankers.

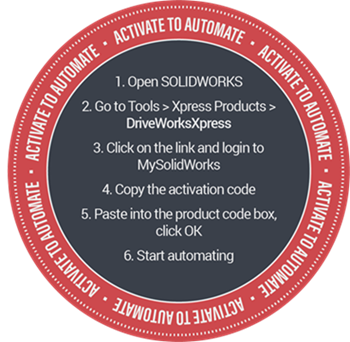

Maria takes up the story again: “We started exhibiting at reseller events around the world, mostly in the US, and we were getting SOLIDWORKS excited about our software. They liked it so much that in 2008, they embedded our entry-level product, DriveWorksXpress, into their software. Everyone who has access to a licence of SOLIDWORKS can use DriveWorksXpress for free!”

The figures tell at least part of the story. The firm has seen 20% growth year on year over the last 14 years – entirely organically through profit alone. As the company has grown, so has the workforce. There are now 45 members of staff at DriveWorks. There has always been an ethos of taking on placements and university leavers, many of whom go on to stay with the firm.

The end users of the various DriveWorks packages are many and varied.

“In 2016 I know there were more than 1,000 unique companies using our products, and we’ve added many more since,” says Maria. “They are mainly from the engineering and manufacturing sectors. DriveWorks has been used to configure architectural and industrial components, windows, heating and ventilation elements, sheds . . . it’s a long list.”

As an individual case study, take Rademaker, which makes industrial bakery equipment in the Netherlands. DriveWorks software has enabled them to improve efficiency and reduce engineering time by 30% across several divisions of the organisation.

“We help our clients to help themselves,” explains Maria. “Our training and education programmes teach companies and students how to automate and become more successful. We give them the skills which will help them in their industry.”

So, what’s next for DriveWorks?

For starters, contingency plans are in place for what Brexit might or might not bring.

“Some 80% of our revenue comes from selling our software overseas so we are doing our bit for UK PLC and keeping a watchful eye but in reality, we don’t know what is going to happen,” Maria continues.

“We have set up a subsidiary in the US and are considering a subsidiary in Europe. One thing we do know is that our software can certainly help British manufacturing companies take their products global by selling digitally anywhere, through a DriveWorks configurator and online presence.

At the moment we are doing a lot of work on 3D visualisation, specifically relating to augmented reality and virtual reality, whereby we set up the configuration of a design and watch it being made. Hardware and the online world are changing all the time. We adapt, embrace and exploit those changes and turn them in to opportunities to deliver value-added software and benefits to our customers.”

“We have only scratched the surface.”