Cubis Systems, headquartered in Northern Ireland is the global leader in Composite Access Chambers and Cable Protection Systems. The company exports to over 30 countries worldwide from operations in 7 manufacturing sites in the UK, Ireland and Australia.

Cubis products are installed in telecommunications networks, alongside railways and motorways, on wastewater treatment works, in power stations and more.

Cubis Systems purchased DriveWorks after identifying a growing demand for bespoke products and solutions. In responding to this market opportunity, Cubis also wanted to enhance the customer experience by including accurate visuals and sales drawings for these custom orders.

They knew that each customer enquiry could result in requests to generate anything from 2 to 60 different sales drawings. This was creating long lead times between the customer’s order and the product being manufactured.

Luke Robinson, CAD/DriveWorks Engineer at Cubis shares how they’ve solved these issues with DriveWorks.

Starting out with DriveWorks Solo

Cubis Systems started their design automation journey with DriveWorks Solo in May 2018 and implemented the software as a sales drawing configurator.

Their first DriveWorks Solo project enabled them to automate the creation of SOLIDWORKS drawings for their modular chambers and composite access frames and covers.

They then developed the configurator to include other product lines, such as cable protection and internal chamber accessories.

Scaling up to DriveWorks Pro

With the configurator successfully automating SOLIDWORKS sales drawings for multiple product lines, Cubis realised they had reached the limits of DriveWorks Solo and upgraded to DriveWorks Pro in June 2018.

Scaling up to DriveWorks Pro has enabled Cubis to take advantage of the DriveWorks 3D functionality.

DriveWorks 3D Preview

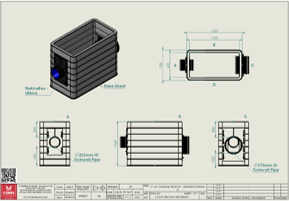

Before using DriveWorks Pro, Cubis didn’t have any 3D models they could use for steel fabrication.

All models were in 2D because of the quantity of customer requests, number of parts and the bespoke nature of the products. Cubis made basic 2D drawings and had to rely on their fabricators on the shop floor to produce these.

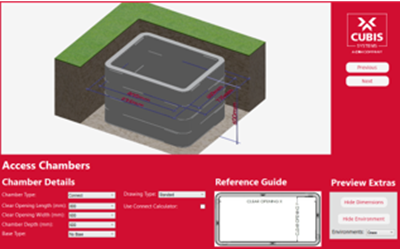

Cubis has now incorporated the 3D Preview functionality in DriveWorks Pro, as it enables their users to understand what they are configuring and subsequently ordering. DriveWorks now generates 3D Previews of all Cubis’s products to give their customers a better feel for their product ranges, improving the end-user experience.

Guiding customers through the sales process is much easier now because the users can physically see how the configured product will look. This even helps identify if a part is going to overlap and therefore shouldn’t be placed in a particular position.

Achievements with DriveWorks

Configurator Look and Feel

Since adding DriveWorks Pro, Cubis has vastly improved UI and User Experience. The image to the right compares Cubis’s DriveWorks powered forms from 2018 and 2021.

The original form did the job, but was basic in comparison to the improved 2021 form which includes more advanced functionality.

The newer form is also in line with Cubis’s company branding, ensuring they remain consistent and recognisable in all areas of their business. This is essential for a global company like Cubis.

Luke highlighted the importance of working closely with the marketing team on form design and UI to ensure that this brand continuity is maintained.

Improving Generation Time

Before using DriveWorks to automate their model and drawing creation, it could take up to 20 minutes to generate a single component. A full system, depending on it’s complexity, could have taken up to a day to create all the required models and files.

Using DriveWorks has significantly reduced Cubis’s generation time, with SOLIDWORKS models and drawings now automatically generating in anything from a few seconds, up to 6 minutes, depending on what is being generated.

One part takes just a few seconds to generate, and a full system containing lots of parts and components can be just 6 minutes.

Automating 100% of Sales Drawing Requests

As of April 2021, Cubis has automated the creation of 15+ different product groups and multiple accessories using DriveWorks. They are also using DriveWorks for almost 100% of sales drawing requests, along with 50% of production drawing requests.

Fast Tracking New Starters

Another benefit Cubis has highlighted since adding DriveWorks is in their training of new starters.

With all the design rules and logic now built into the DriveWorks Configurators by Luke, a recent new starter was able to generate full system drawings via DriveWorks on his second day with the company.

Previous new starters could spend 3 months learning just one product group.

Plans for the Future

Since adding DriveWorks, Cubis has achieved some impressive time savings, but this innovative company don’t want to stop there.

The next step of their DriveWorks implementation will allow Cubis to take their DriveWorks powered configurator to their customers, enabling their sales team to generate specifications on site, enhancing customer engagement and experience.

Cubis also plan to take advantage of DriveWorks’ integration capabilities to integrate with their company’s chosen ERP system. This will enable Cubis to automate their part creation process and save even more valuable time.

We look forward to following their progress!

For more information about Cubis Systems and their products, visit www.cubis-systems.com

Suitable for Any Industry

DriveWorks product configurator software is used by companies of all sizes. It’s suitable for any industry where quotes or 3D files and drawings are part of the sales to manufacturing process.

See how versatile and customizable it is by having a go with our online configurator examples on www.driveworkslive.com