A-LINE Building Systems are a market leading manufacturer of steel buildings, sheds, barns, carports and farm out-buildings.

With over 20 year’s industry experience, their innovative concepts and range of engineering resources are reflected in the strength, durability and detailing of their products.

Designing to Order Before DriveWorks

Before using DriveWorks, A-LINE created all of their quotes manually. This was very time consuming and they wanted to implement a solution that could be used by their sales teams, distributors and dealers to quickly provide quotes and drawings.

Automating the Design Process

When we last interviewed A-LINE, they were using DriveWorks Pro Administrator, Autopilot and Live to automate their design process when creating custom sheds.

This involved creating customised forms within their DriveWorks project which were embedded into their website. This allowed their customers to easily specify the requirements for a shed and receive live pricing updates, a quote and a PDF of the drawings.

Using DriveWorks enabled A-LINE to create up to 200 designs per day, which gave them a huge competitive advantage in the marketplace.

A-LINE have recently invested more time into improving and advancing their DriveWorks project. They’ve made a lot of changes behind the scenes, which have given their users greater flexibility when using the quoting system. We recently caught up with their Automation Specialist, Nayshil Singh, who told us more about the updates to their DriveWorks configurator.

An Impressive New Home Page

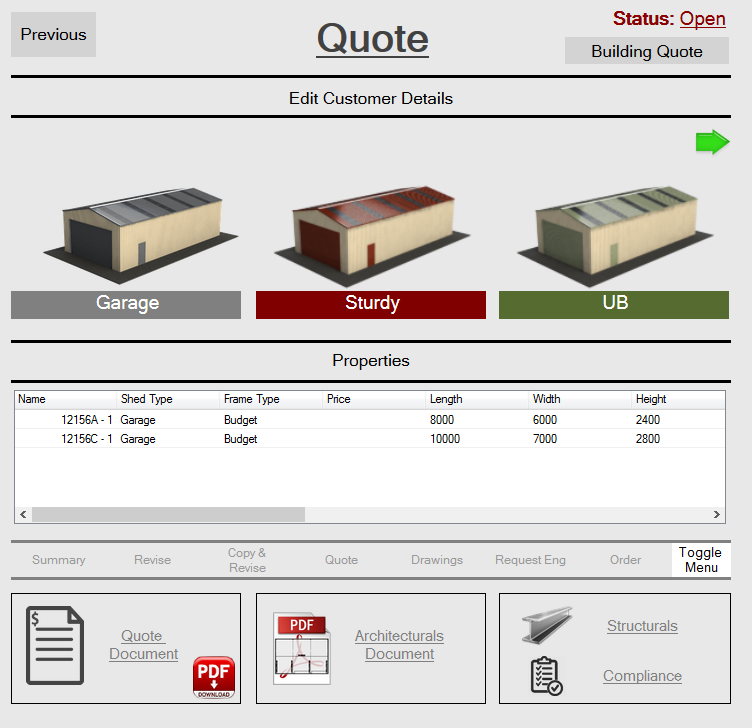

“We’ve recently updated our home page and it now enables users to create multiple quotes at once. This was achieved using the DriveWorks Child Project Control which allows users to specify many types of sheds at the same time whilst also comparing prices.”

“Using the table highlighted to the right, sales people can select which quote they wish to edit and open it by clicking the ‘Quote Document’ button. The quote is obtained directly in the browser within seconds so the sales person no longer needs to wait for an email. The emailed quote is simply used for our records.”

“Drawings can also be viewed directly in the browser once the model generation has been completed. The headers of the tables are also customizable, so the sales person can display any shed property that they like.”

A Quote Management Area

“We’ve also created a new quote management area which allows the sales person to view their past quotes in one place quickly and easily.”

“Users can search and filter quotes by numerous properties and view / track all documents linked to the quote, such as compliance certificates or engineering drawings. They can also upload documents that may help them during the quoting process.”

Behind the Scenes Updates

A-LINE have also made a lot of changes behind the scenes which are not obvious to the user but give them greater flexibility when using the quoting system.

These include:

- The ability to save quote progress and finish it at a later date.

- A-LINE have used the ‘Continuously Synchronize’ function of DriveWorks Child Specifications to predict drop out behaviour ahead of time. The system now alerts the user, through an error message, that they need to return to a Child Project and fix the drop outs.

- They’ve also used a DriveWorks Specification Power Pack function to group quote items in order to determine the quantity. For example, if a shed is quoted and it has 10 RAD openings, the quote will now show ‘10’ in the quantity field rather than list each one as a separate line item. They used the ‘SPPSUMTABLEBYGROUP’ function to determine when to group items together.

“Maintaining our professional appearance is very important to A-LINE Building Systems. Automating our quoting process using DriveWorks has helped us to save time, money and reduce errors, without compromising on quality or professionalism.

– Craig Barker, Director.

The new system benefits our customers as it enables our sales team to easily provide accurate quotes and drawings. This helps us to provide great customer service and also get the order to our manufacturing department quicker than before.”

– Craig Barker, Director.