When working with SOLIDWORKS®, the complexity of custom design projects with multiple configurations means additional tools are needed for achieving efficient workflows, maintaining accuracy, and boosting productivity.

Regardless of what you’re designing, integrating DriveWorks into your design process can enhance your SOLIDWORKS experience. In this blog we’ll explore three areas that DriveWorks adds real value to your SOLIDWORKS workflows, with a focus on smart file management, business and engineering rules, and drawings.

Smart file management

Handling large volumes of complex design files is a challenge for design engineers. DriveWorks technology enables efficient and smart file management of SOLIDWORKS design files to streamline workflows.

DriveWorks simplifies file management by:

- Enabling intelligent file naming

- Re-using not re-creating files

- Saving generation time by using previously created models

- Splitting out different configurations into separate files to improve design process times and reducing file storage requirements

- Saving drawings out in additional file formats, such as PDF, JPEG, DWF, and DWG

- Enabling scheduled automation of tasks e.g overnight

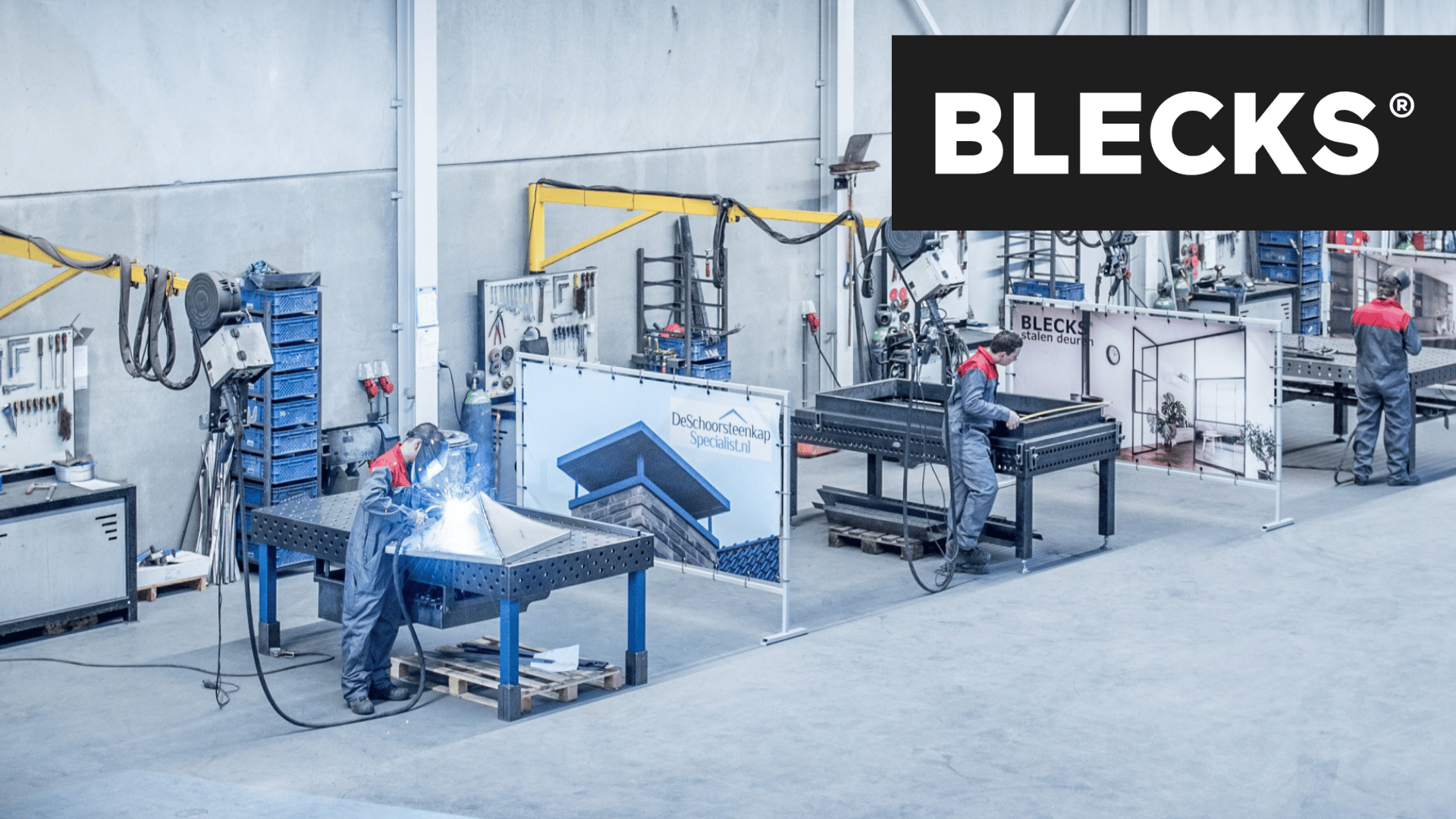

Blecks, based in The Netherlands, supply and manufacture chimney caps, steel doors and steel stairs. Blecks have automated the cutting of parts for their chimney caps using DriveWorks. DriveWorks drives the generation of 2D drawings, part lists and .dxf files for laser cutting. Information is passed into SOLIDWORKS custom properties which is then etched onto each part to help identify it after cutting. Using DriveWorks rules, generated files are saved with dynamic names, allowing the files to be sorted by thickness or material.

Business & engineering rules

For consistent, rules-driven designs, DriveWorks plays a key role in enforcing engineering and business constraints and standards in SOLIDWORKS designs and workflows.

DriveWorks technology enables you to:

- Build rules using external data and considerations

- Apply different rules to different designs

- Set different rules for different markets

- Ensure design and regulatory compliance

- Eliminate costly errors and rework

- Free up design engineers from mundane & repetitive tasks so they have more time to focus on new product designs

“Manufacturing fire rated steel doors for both the UK and European markets require strict adherence to both local regulations and international standards. At EBD Steel Doors, the scope of our product offer and our commitment to provide our customers with bespoke doors designed for their specific application, the adherence of the design to these standards can be complex.”

Using DriveWorks, we are easily able to control all aspects of the door that are affected by these standards (such as limiting the size of the door and the selection of ironmongery and other door furniture based on previous selections).

This ensures that the design output is fully compliant with these standards and all the design rules are applied consistently throughout our product offer. This is all controlled centrally within DriveWorks from a group table that ensures all the DriveWorks projects are referencing a single data source. This single source allows for quick and easy updates to be applied and gives us the confidence that all of our designs adhere to the latest standards.”

– Design Manager, EBD Steel Doors

Drawings

DriveWorks enables enhanced SOLIDWORKS drawing automation. Using DriveWorks technology, design engineers can save time and boost product quality by automatically creating accurate SOLIDWORKS manufacturing drawings.

DriveWorks technology provides:

- The ability to control sheets, views, annotation text, annotation positions, layers, break lines, and custom properties

- Generation reports providing a complete audit trail of drawing values

- Drawings saved out in additional file formats, such as PDF, JPEG, DWF, and DWG

- Prioritized drawing generation to speed up quote & sales cycles

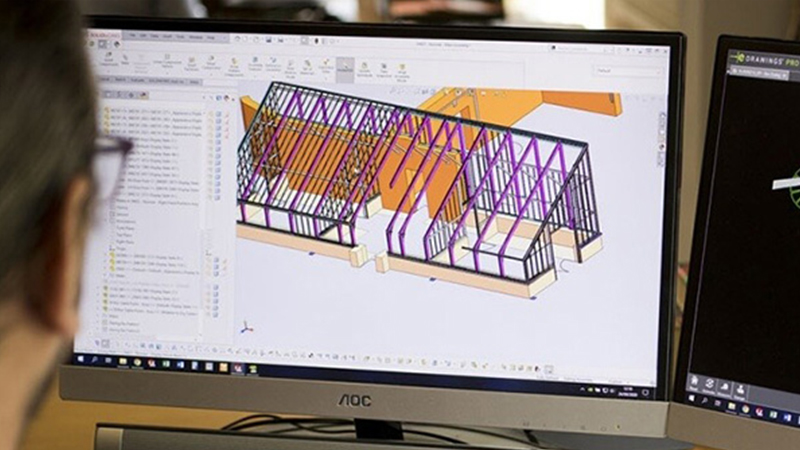

Alitex, headquartered in the UK, designs and manufactures bespoke aluminum greenhouses and conservatories for customers around the world. Alitex use DriveWorks to automatically generates documents and data for their Manufacturing team. This includes a Bill of Materials, CAM information, and drawings.

DriveWorks also automatically generates ground plan drawings for each bespoke product. This provides the builder with the information they need to build the base and gives the customer a visual representation of the product they will receive.

Alitex has been able to halve its design time, to just 20 hours. The saved time is spent developing the product and design process to further enhance the customer experience.

Get started with DriveWorks

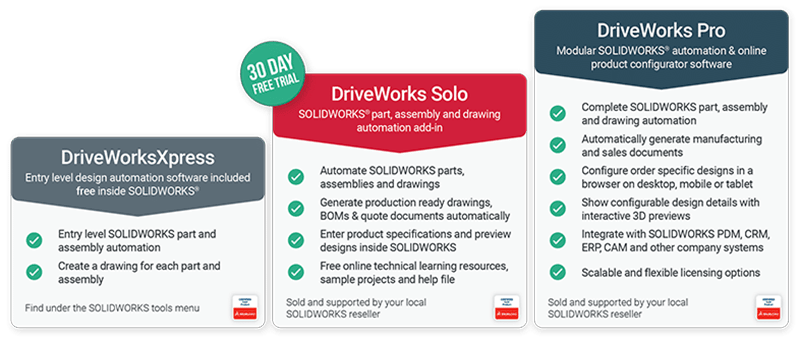

Get started with any DriveWorks software and upgrade as your requirements change.

DriveWorksXpress is the free design automation tool you already have inside SOLIDWORKS®. Activate your free license of DriveWorksXpress in the SOLIDWORKS® tools menu.

Try DriveWorks Solo

Start your free trial today and get instant access to DriveWorks Solo for 30 days. No credit card required.