Estimated reading time: 7 minutes

What is design automation?

Custom products are often ‘the same, but different’, sharing a common design that is customized to meet the specific needs of the customer.

Preparing engineering data for a custom product typically involves an engineer copying existing 3D CAD models and updating dimensions, suppressing and un-suppressing features, and replacing components to meet the client’s specifications. Once the 3D CAD models have been updated, drawings, BOMs and cut lists can be created.

Design automation tools capture and reuse design, process, manufacturing, and cost estimation knowledge to automatically create the documents and data required to sell and manufacture custom products.

How does design automation work?

Capturing CAD files

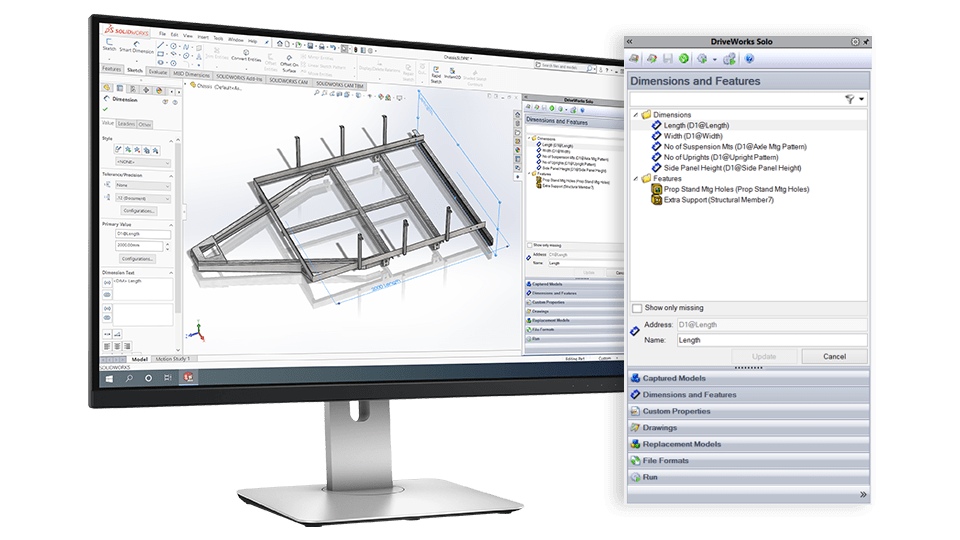

Design automation solutions need to capture the parameters engineers manually update to prepare CAD files. Capturing the parameters means they can be automatically changed and updated. This involves identifying which parameters need to be updated and saving them in the design automation tool, with a name that is easy to identify.

For example, the dimensions that control the size of a trailer chassis might be captured and named ‘Length’ and ‘Width’. And a structural member feature that is added if the trailer length is above a set size might be named ‘Extra Support’.

Capturing CAD Files

The parameters engineers manually update to prepare CAD files for a custom enquiry are saved in the design automation tool. They can then be updated programmatically.

Capturing engineering knowledge

The next step is to capture the knowledge of the people who manually update the parameters in the CAD files, so the design automation tool can automatically make the updates.

DriveWorks captures the knowledge and actions of engineers using rules. DriveWorks rules can be equations, sums, business logic, legislation, and product requirements. They can be simple actions, complex calculations, or a series of instructions. Rules can also use information from databases, web services, and integrations with other company systems.

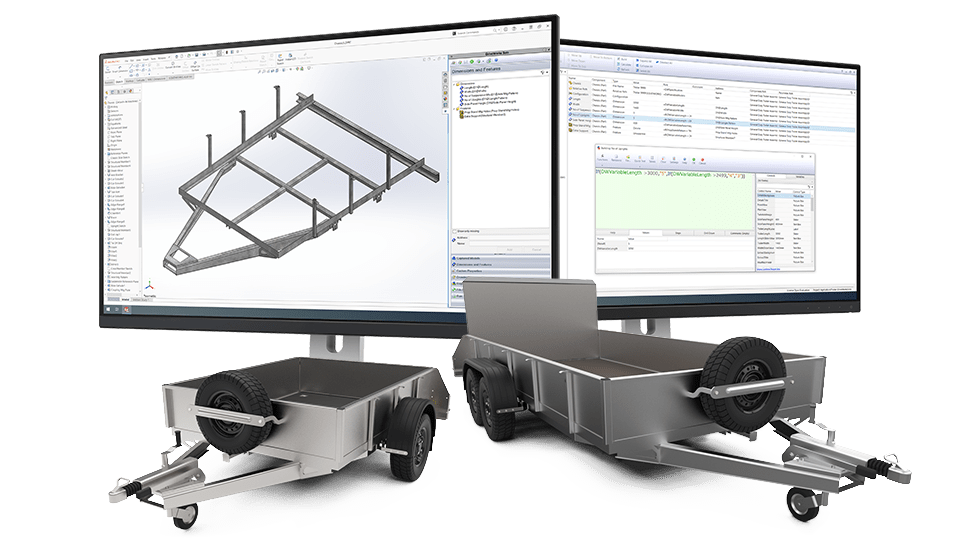

Capturing Engineering Knowledge

The design and engineering knowledge of the people who manually update the parameters in the CAD files is captured in rules.

DriveWorks rules use an Excel-style syntax so they’re easy to learn and use. There are over 200 functions to make capturing even the most complicated processes simple.

Specifying product requirements

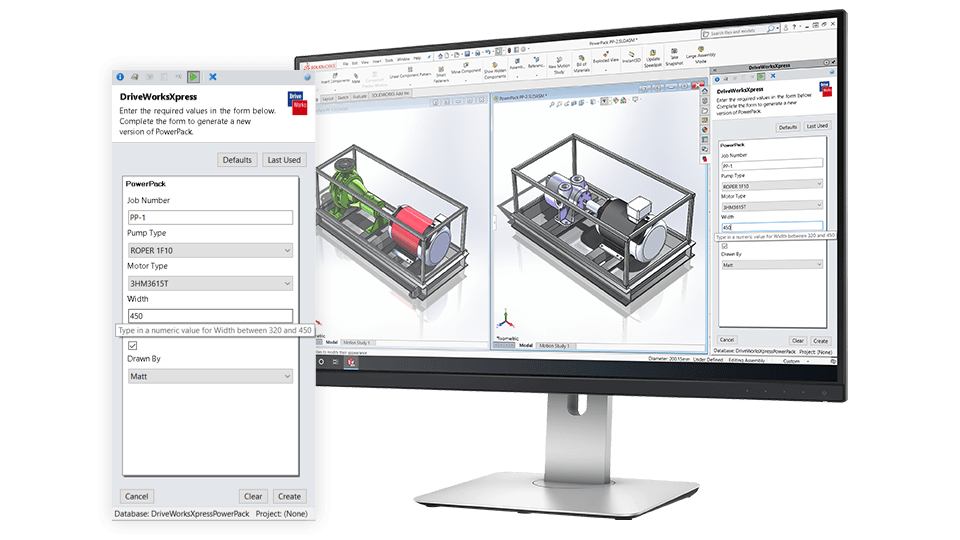

New configurations are specified by entering product requirements into a custom-designed User Interface (UI). The values entered are used in the rules to automatically update the 3D CAD files and create the manufacturing and sales documentation required.

Entering product requirements

Product specifications are entered into custom forms.

Depending on your requirements and the design automation tool that you use, entering the product specification can be completed by the engineering team, internal sales team, distributors, or even the customer.

Benefits of design automation

Solving the demand for skilled people

Building a team with the skills you need can be challenging. Design automation enables the knowledge and experience of your team to be captured and reused, enabling you to overcome the challenges of not being able to recruit the right people.

By automating what are often repetitive, time-consuming tasks, existing team members are freed up to focus on increasing throughput, solving custom design challenges, and improving existing products and processes.

Saving time, reducing errors, and increasing productivity

Design automation is consistently accurate and significantly quicker than manually preparing files. Once a design automation solution is set up and has been tested, it will reliably output predictable results. Combined with a custom UI that standardizes the input of values and ensures that the data entered is in the correct format, you can be confident that the files created will be accurate and free of errors.

Quoting custom products without engineering input

Quoting custom products typically requires engineering teams to prepare drawings for speculative orders. This is a significant draw on engineering resources.

Design automation enables engineering and design intent to be used by sales teams to quote custom products accurately, and automatically create approval drawings, BOMs, and associated sales documentation within minutes.

Responding to enquires quickly improves the customer experience and can provide a competitive advantage.

As simple or complex as you need

New configurations are specified by entering product requirements into a custom-designed User Interface (UI). The values entered are used in the rules to automatically update the 3D CAD files and create the manufacturing and sales documentation required.

Depending on your requirements and the design automation tool that you use, entering the product specification can be completed by the engineering team, internal sales team, distributors, or even the customer.

Integration with other company systems

Configuring custom products and preparing the documents and data required by sales and manufacturing usually requires data to be shared and updated across various company systems.

Using a design automation tool that supports integrations ensures that consumed information is always up to date. Automatically updating information in other company systems is faster and removes the risk of introducing errors during manual data entry.

For example, you may use information from your ERP system to gather accurate information on production dates to support sales with accurate lead times. Or you could use information from a REST API to retrieve accurate shipping information.

Easy to setup, maintain, and use

New configurations are specified by entering product requirements into a custom-designed User Interface (UI). The values entered are used in the rules to automatically update the 3D CAD files and create the manufacturing and sales documentation required.

Depending on your requirements and the design automation tool that you use, entering the product specification can be completed by the engineering team, internal sales team, distributors, or even the customer.

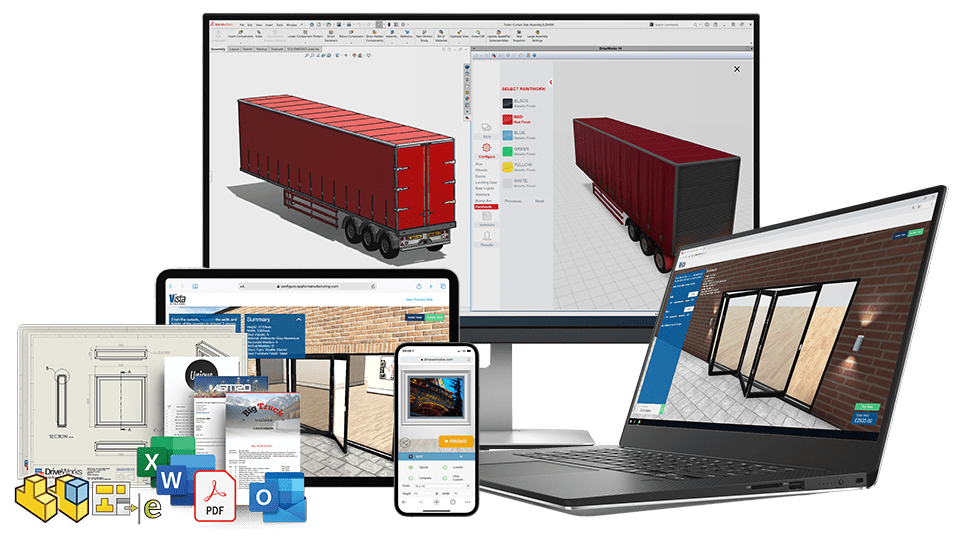

Build an online product configurator

Using a design automation tool that allows you to share your custom UI online is the foundation of an online product configurator.

Product Configurator

Configure custom products on any device and automatically generate sales and manufacturing data.

Embed your configurator into your company website as an online sales configurator and enable your sales teams, distributors, dealers, and customers to configure and order customized products anytime, anywhere, on any device.

Explore our examples at www.driveworkslive.com to see how you can use DriveWorks to build an online product configurator.

Get started with DriveWorks for free

If you’ve got SOLIDWORKS, you’ve already got design automation. DriveWorksXpress is a free design automation tool, installed inside every license of SOLIDWORKS. Find it in the tools menu, activate it, and start automating.

Take design automation even further with DriveWorks Solo. Download a 30-day full feature free trial of DriveWorks Solo to see what you could achieve.