Estimated reading time: 5 minutes

Digital transformation for manufacturers

Digital tools are transforming the way manufacturers operate. In this article, we’ll look at ways manufacturing companies selling configurable products can use digital tools and the benefits they offer.

What is digital transformation?

Digital transformation is the use of digital tools to create new or optimize existing business and manufacturing processes. There are two key parts to digital transformation:

Digitization is the process of moving data into digital formats. For example, this could be the transition to capturing customer requirements digitally using a product configurator.

Digitalization is the use of digital data to improve processes. For example, using the digital data captured by a product configurator to automatically create sales documents and CAD data for manufacturing and update company systems like ERP and CRM.

Why is digital transformation important?

Leveraging technology is essential for manufacturers of complex, configurable products to meet customer expectations and stay ahead of the competition. Digital tools help organizations to:

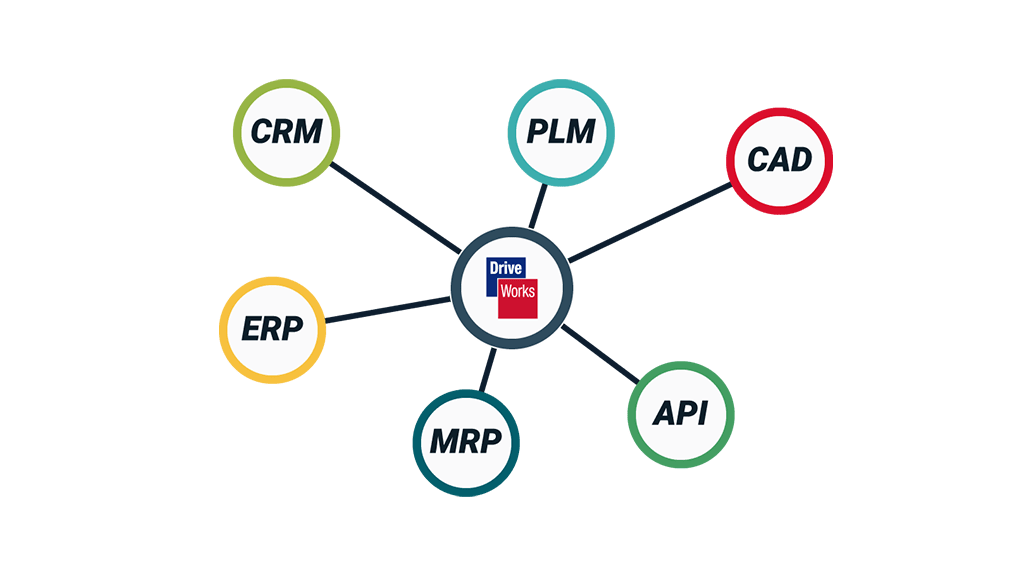

Integrate data

Integration involves connecting the different systems your organization uses so they can automatically share information. It’s essential to the success of digital transformation. Connecting systems improves data accuracy and ensures information is always updated, as manual data entry is removed.

Automatically share information between company systems

Integrations also make it easy to access the information you need to make informed business decisions and monitor performance. It’s important to ensure that any digital tools you choose can integrate and automatically share data with the other systems. Having siloed information in systems that can’t integrate and share data will restrict what you can achieve with digital tools.

Streamline sales processes

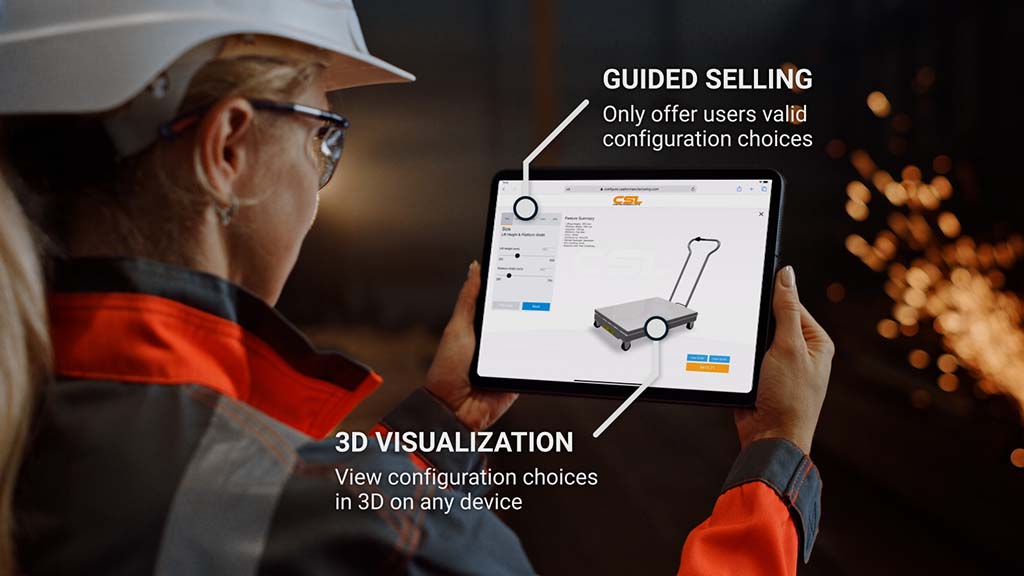

Ensure that only valid configuration options are available

Configuring complex configurable products is challenging. Configure, price, quote (CPQ) applications support sales teams with features that streamline sales and enhance the customer experience.

- Configure

Product configurators remove the challenges of specifying complex configurable products. Guided selling features ensure that only valid configuration options are available and can offer personalized recommendations using previous configuration choices. This empowers sales teams, distributors, and even customers to configure custom products accurately. 3D visualization tools help to communicate complex design details easily, enabling customers to understand product options as they configure. Not only does this improve the user experience, but it also reduces the likelihood of design revisions once the quote has been sent. - Price

Pricing and discounts are calculated by the product configurator in real-time as you choose options, helping customs balance product requirements and budget. - Quote

Sales documents such as quotes are automatically created and emailed to the customer, saving sales teams valuable time that can be used on driving new business.

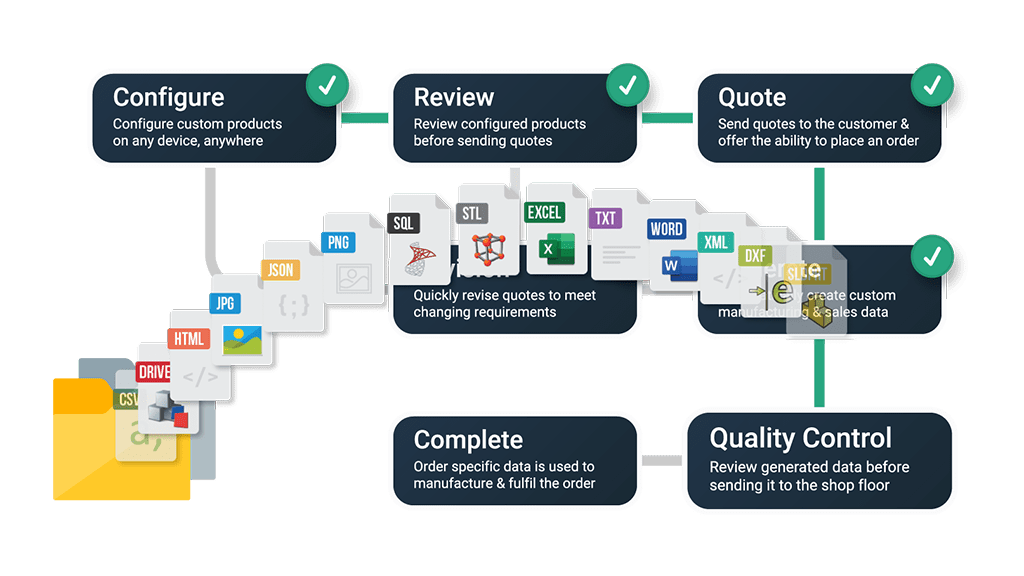

Automate engineering processes

Manufacturers selling custom products typically require custom engineering data to be prepared for each quote and order. Without automation, the time-consuming task of manually preparing drawings for sales inquiries can be a bottleneck in the sales process. It also puts the engineering team under pressure.

Data and documents for sales and manufacturing are created automatically

CAD automation enables engineering teams to automate repetitive, time-consuming design tasks. This makes it quicker to prepare engineering drawings for quotes and orders and frees up the engineering team to focus on high-value activities.

Automate business processes

Automating the ongoing tasks required for a business to function, leaves capacity and agility for your team to respond rapidly to changes in the market and enables you to stay ahead of the competition. For example, sales teams often use valuable time getting quotes approved by engineering. Automating or removing the need for these tasks frees up sales to focus on driving new business.

Overcome skill shortages

Finding and retaining people with the skills you need can be challenging. Digital tools help to combat staffing challenges by automating business and engineering processes. For example, CPQ solutions reduce the need for salespeople to have the same technical understanding and product knowledge before they can successfully sell. Leveraging these digital tools gives organizations access to a larger pool of workers whilst also reducing onboarding time.

Gain insights from data

Digital tools make accessing data that informs business decisions easier than ever before. In many cases, integrations enable the information to be automatically pulled from the different digital tools your organization uses into a centralized dashboard.

Try DriveWorks demos

Explore example configurators built using DriveWorks software to see what you could achieve.