Manufacturers of custom products often place significant pressure on their design engineers, needing them to produce proposal documents and drawings quickly. Engineering departments find themselves wasting skilled effort on tasks that could be automated. They have less time to re-engineer existing designs, update drawings, and thoroughly check design details. Jobs are left open to errors, rework, backlogs, and delays. All of this can hinder growth and damage profit margins.

Design automation addresses these challenges by streamlining manual tasks in traditional CAD workflows and company-wide processes across sales, engineering, and manufacturing. By automating time-intensive and repetitive design engineering activities, manufacturers increase throughput, improve quality, and have greater success in winning new business.

What is design automation?

Design automation simplifies the design process for “same but different” products by using predefined rules and logic to control parameters in CAD models, assemblies, and drawings.

Design automation solutions automate repetitive engineering design tasks such as creating drawings, adjusting product design parameters, or applying specific design rules.

Design automation for SOLIDWORKS®

DriveWorks design automation technology enables manufacturers to capture and reuse design, manufacturing, and cost estimation knowledge to deliver custom products faster and with greater accuracy, without using complex macros, design tables, or configurations.

DriveWorks is exclusively designed for SOLIDWORKS, making it the ideal choice for any manufacturing company using SOLIDWORKS 3D CAD. DriveWorks is committed to delivering innovative solutions and has been recognized with SOLIDWORKS Certified Gold Partner status since 2002.

How does DriveWorks design automation for SOLIDWORKS work?

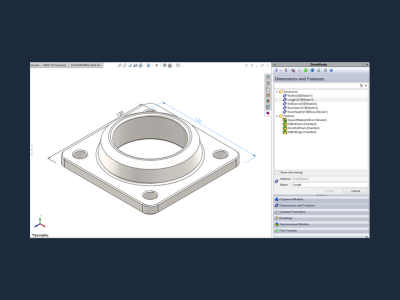

Step 1: Capture parameters

Identify and capture the parameters you modify manually in your SOLIDWORKS models, assemblies, and drawings using the DriveWorks Add-in.

Step 2: Build rules and logic

Use the intelligent DriveWorks Rules Builder to encode your engineering knowledge into rules that update and control these parameters.

Step 3: Run your automated design project

Run your automated design project to quickly generate SOLIDWORKS files tailored to specific customer requirements. Create accurate models, assemblies, drawings, and BOMs, based on the rules you’ve defined.

Benefits of DriveWorks design automation for your business

Improved efficiency

DriveWorks design automation solution streamlines workflows, enabling faster design iterations with minimal manual input. By automating repetitive tasks, project timelines are shorter, enabling engineers to take on more projects or dedicate time to solving complex challenges. Improved workflows also enhance collaboration across departments, optimizing processes in sales and production.

Focus on innovation

When mundane tasks are automated, design engineers have more time to concentrate on creative problem-solving and new product development. This fosters a culture of innovation and accelerates time-to-market for new launches. Engineers also experience greater job satisfaction, as they spend more time on engaging, high-value tasks. Providing engineers with engaging and fulfilling work helps improve employee retention by reducing frustration and boredom.

Cost savings

With DriveWorks design automation solution, you achieve faster project completion, reduced errors, and fewer labor hours, all leading to significant savings. By minimizing bottlenecks and errors, you can deliver custom products quickly, enhancing customer satisfaction and boosting repeat business.

Reliable accuracy and quality

DriveWorks design automation reduces the risk of human error, ensuring accurate and reliable outcomes. This is particularly important in manufacturing, where accuracy is critical to smooth operations across design, sales, and production teams. Predefined design rules and parameters prevent rework, and automated systems produce results quicker and more consistently than manual methods.

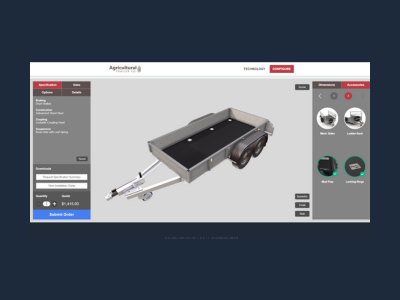

Scalable customization

The demand for customizable products is growing across all industries. However, manual CAD design for custom products is slow and error-prone. Design automation addresses this challenge by generating 3D models, manufacturing data, and drawings automatically, making it easier and faster to deliver high-quality, customized products to market at scale.

Speeding up sales & manufacturing processes with DriveWorks design automation

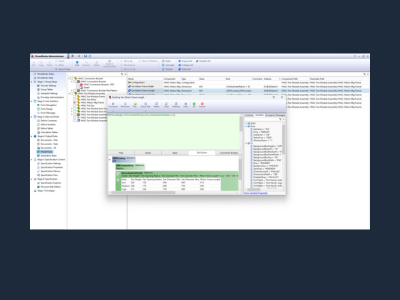

VanAire Inc, headquartered in Michigan, USA, develop engineered valve automation hardware, predominantly working with metal parts that connect valves and actuators on pipelines. VanAire started using DriveWorks in 2006 to automate their design process. DriveWorks is now implemented into many of their systems, speeding up processes and order cycles. VanAire’s ERP system is integrated with SOLIDWORKS and DriveWorks, further streamlining their order process.

Before implementing DriveWorks, the manual process of creating a specification and inputting it into the ERP system could take up to two hours. Using DriveWorks, this process now takes less than 10 minutes.

Using DriveWorks design automation technology, manufacturing data and drawings are also now created automatically. This process used to take 15-20 minutes and has now been cut down to 3-4 minutes, including generating all the manufacturing data and drawings.

“DriveWorks has made the whole process from the customer’s initial inquiry, to getting a quote and receiving their order, much easier and quicker.“

– Ismeal Lopez, CAD Administrator at VanAire Inc.

DriveWorks design automation solution is used by manufacturing companies from a range of industries. Because DriveWorks technology is modular, scalable, and incredibly versatile, customers use the technology in many different ways, building design automation solutions to suit the needs of their own businesses.

Seeing how other companies use DriveWorks is a great way of understanding how DriveWorks technology works. It enables you to see how manufacturers have adopted the technology across a range of different industries and the benefits they’ve achieved with design automation.

Get started with design automation today

DriveWorksXpress entry-level design automation is included free in every seat of SOLIDWORKS®.

SOLIDWORKS users looking for a more comprehensive design automation experience can also download a 30 day free trial of DriveWorks Solo. Make the most of your free trial by setting clear goals, testing key features on real projects, and making the most of a whole host of free training material. Use the time to evaluate its impact on your workflows and ensure it meets your needs. You can also set up a meeting with a technical expert from the DriveWorks team to help you get off to the best start.