Manufacturers of custom products are under pressure to find new ways to improve efficiencies and drive sales. For businesses that sell products with complex configurations, a Configure, Price, Quote (CPQ) solution is often the go-to solution for faster quoting and sales cycles, and efficient customization.

However, traditional CPQ solutions can be complicated to set up, requiring coding expertise and long implementation times. They are also often difficult for sales teams to use, requiring an investment in training. This can create bottlenecks for engineering and sales teams and reduce the business benefit of the solution.

DriveWorks CPQ for Manufacturing is easy to set up for design engineers – with no coding or programming skills required – and intuitive for sales teams and customers to use, with 3D product visualization and guided selling features. Additionally, manufacturing teams benefit from improved accuracy and less rework. In this blog we explore how DriveWorks CPQ for Manufacturing can transform how manufacturers configure, price and quote their custom products, enabling their design engineers, sales, and manufacturing teams to work more efficiently.

Simplicity in CPQ set up

Traditional CPQ solutions often come with a steep learning curve. Some require significant custom development or programming to adapt them to specific products. For design engineers involved in the set up this can be a lengthy and time-consuming process, and may even require external resource. This can impact the implementation timeline and impact on employee buy-in.

With DriveWorks CPQ for Manufacturing, design engineers can easily set up product configuration without needing to write any code. With user-friendly interfaces, they can easily upload product data, set configuration rules, and define pricing models. All without the need for any programming skills. DriveWorks design automation for SOLIDWORKS enables design engineers to create even the most complex of configurations in the minimum amount of time. Reducing repetitive and mundane tasks enables engineers to focus on what they do best – new product development and innovation.

Enhancing sales with 3D product configuration and guided selling

Some CPQ tools can be clunky and difficult to use, especially when the product is highly customizable. Sales reps may struggle to accurately configure products, resulting in errors or delays that can frustrate both the sales team and customers. For customers, navigating these systems can also be confusing, especially when trying to visualize complex products.

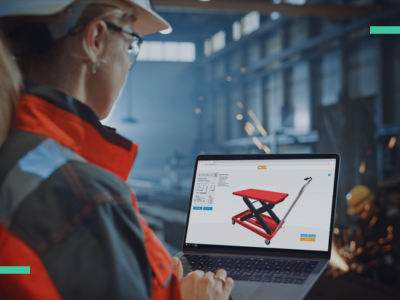

DriveWorks CPQ for Manufacturing is an intuitive solution that combines 3D product configuration and guided selling features.

3D product configuration

With 3D product configuration, sales teams (and customers) can interact with a visual representation of the product as they customize it. This is especially useful for complex products like machinery, vehicles, or modular systems, where seeing the product in 3D helps both the sales rep and the customer make informed decisions.

As sales reps make adjustments – changing sizes, colors, components, or features – the 3D model updates in real time, giving a clear picture of what the final product will look like. This reduces confusion and miscommunication, making it easier for the customer to commit to a purchase. The 3D configuration tool also improves accuracy by automatically enforcing configuration rules, ensuring that only valid combinations are presented to the customer.

Guided selling

Guided selling is another feature of DriveWorks CPQ for Manufacturing. It acts as a digital sales assistant, guiding sales reps through the process of configuring a product based on the customer’s unique needs. The system asks questions and provides suggestions, narrowing down the options to only those that meet the customer’s specifications.

Its particularly helpful for sales reps who aren’t familiar with every technical detail of the product. By providing a structured, step-by-step process, guided selling ensures that sales reps can confidently create accurate configurations and quotes without needing to be product experts. For customers, guided selling can enhance the experience by making it easier to explore options and make the right choices.

Benefits for manufacturers

According to research from PWC, companies who have a CPQ tool report significant improvements on key business metrics across the sales lifecycle, including a 10-15% increase in revenue.

Implementing DriveWorks no-code CPQ solution with 3D product configuration and guided selling provides several benefits across design, sales and manufacturing teams:

Faster time to market

With an easy-to-set-up platform, design engineers create product configurations faster, enabling quicker quote and sales cycles. With more time available to work on new product design, the speed to market for new products and product updates is also improved.

Reduced errors

By automating configuration rules and providing real-time visual feedback, the system ensures that only valid product combinations are offered, reducing the chances of errors in the sales process and less rework at the manufacturing stage.

Scalability

As businesses grow, product offerings and configurations often become more complex. DriveWorks CPQ scales with you, easily handling new product variations and pricing models without the need for extensive IT involvement. Increased custom orders can be easily handled by sales, design and manufacturing teams.

Increased sales efficiency

Sales reps spend less time learning the technical details of every product and more time closing deals. The intuitive nature of DriveWorks CPQ enables them to generate accurate quotes quickly, even for complex custom products. Guided-selling technology also enables sales teams to identify relevant upgrade and add-on options, increasing average sales values.

Improved customer experience

Customers benefit from being able to visualize the product in 3D, making the purchasing process more interactive and engaging. Guided selling helps to navigate complex product options with ease. Improved customer experience also leads to better customer retention.

Using DriveWorks CPQ to Increase Sales Cycle Efficiency

Autex Acoustics Ltd, based in New Zealand, specialize in the development and production of innovative interior acoustic and insulation products. Autex wanted to improve their efficiency when closing deals, reduce their quote cycle times and enable their sales team to sell more. Building a robust CPQ solution using DriveWorks technology enabled them to achieve these goals.

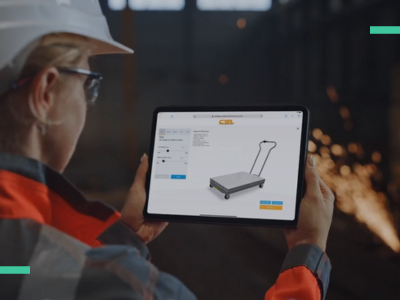

Autex use the ready-made DriveWorks CPQ DriveApp for their CPQ solution. Their CPQ platform enables their sales team to create and manage custom quotations. When a custom line item is added to a quote, an interactive DriveWorks configurator is shown, enabling users to configure each product and see live pricing updates.

Using dynamic rules inside DriveWorks, Autex display a full price breakdown. When configuring their product, users can see separate material costs, cutting costs and component costs, enabling them to see immediately how design changes impact the overall price.

When an order has been processed, DriveWorks triggers the automatic generation of their SOLIDWORKS® files, creating a seamless workflow between sales, design engineering, and manufacturing.

Accessing their CPQ system through a browser enables Autex’s sales team to configure products anywhere, on any device. They can also review and download all necessary documents from one place inside the browser.

The workflow set up in Autex’s CPQ system enables cross departmental teams to track the progress of each quote or order, improving the efficiency of communication between teams. Autex customized their CPQ solution using DriveWorks project and form templates. This made it easy for them to add their own rules and logic to create a custom user interface that matches their company branding.

“Using DriveWorks has helped us automate design processes to free up valuable design team resources and provides our customers with quick, professional and accurate quotations for our Acoustic Solutions”

Dwane Brown, Group Technology Manager at Autex

DriveWorks CPQ for Manufacturing

Configure, price, quote and manufacture custom products faster and with greater accuracy.