As a result of the demand for custom products across a wide range of sectors, the ability to streamline processes and maximize efficiency is a challenge for many businesses.

Design automation together with CPQ technology enable businesses to efficiently design, sell, and manufacture custom products.

But what exactly is design automation?

Understanding Design Automation

Design automation is the process of using rules-based logic to automate the creation, configuration, and customization of product designs. It enables organizations to generate complex product configurations quickly and accurately, based on predefined parameters and rules.

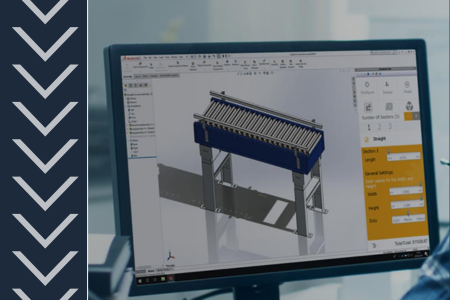

Preparing engineering data for custom products typically involves an engineer copying existing 3D CAD models and updating dimensions, suppressing and un-suppressing features, and replacing components to meet the custom specifications. Once the 3D CAD models have been updated, drawings, BOMs, and cut lists can be created.

Design automation tools capture and reuse design, process, manufacturing, and cost estimation knowledge to automatically create the documents and data required to sell and manufacture custom products. By automating tasks within a design workflow, engineers have more time to focus on other important tasks, such as reworking existing designs and double-checking details.

Businesses across a wide range of industries use design automation tools to streamline their product design workflows.

Whether it’s designing customized machinery, architectural structures, or consumer goods, the ability to automate repetitive design tasks not only accelerates the time-to-market but also minimizes errors and ensures consistency in the final product.

70% of businesses are piloting automation technologies

In a 2022 study by McKinsey & Company, 70% of businesses said they are piloting automation technologies in one or more business functions.

88% of businesses said that automation enables them to compete with larger companies

In a recent automation survey, 88% of small to medium businesses said that automation allows their company to compete with larger companies.

The DriveWorks Design Automation Difference

Design automation speeds up the design of custom products, cuts costs, and helps reduce errors. When combined with a CPQ solution, orders are placed and manufactured even faster. It enables seamless communication between all teams involved, boosts sales, and improves productivity.

DriveWorks seamlessly integrates with SOLIDWORKS® to enable rules-based SOLIDWORKS automation.

By defining rules and logic, DriveWorks design automation technology ensures that every configuration complies with a set of predefined rules and specifications. This not only removes the risk of errors but also enables customers to see a range of different product options without compromising feasibility or manufacturability.

The Value of Rules-Based CPQ

By defining rules and constraints at every stage of the configuration process, businesses can reduce the risk of offering unfeasible or non-compliant product configurations. This not only streamlines the sales process but also minimizes costly errors and rework.

CPQ makes complex configurations easier to sell. Sales reps and customers can quickly and easily configure products using a 3D configurator. With in-built rules working behind the scenes, the configurator automatically checks for compatibility, adjusting options and pricing to a set of pre-determined rules. It ensures the final configuration is feasible for production.

DriveWorks design automation and CPQ for Manufacturing technology solutions automatically generate 3D models, specifications, BOMs, and CAD drawings, so the engineering department receives a complete and accurate breakdown of the custom product requirements. This ensures accuracy in engineering design and removes the need for lengthy dialogue between sales and engineering design teams.

How are DriveWorks Customers Benefitting from the Design Automation Difference?

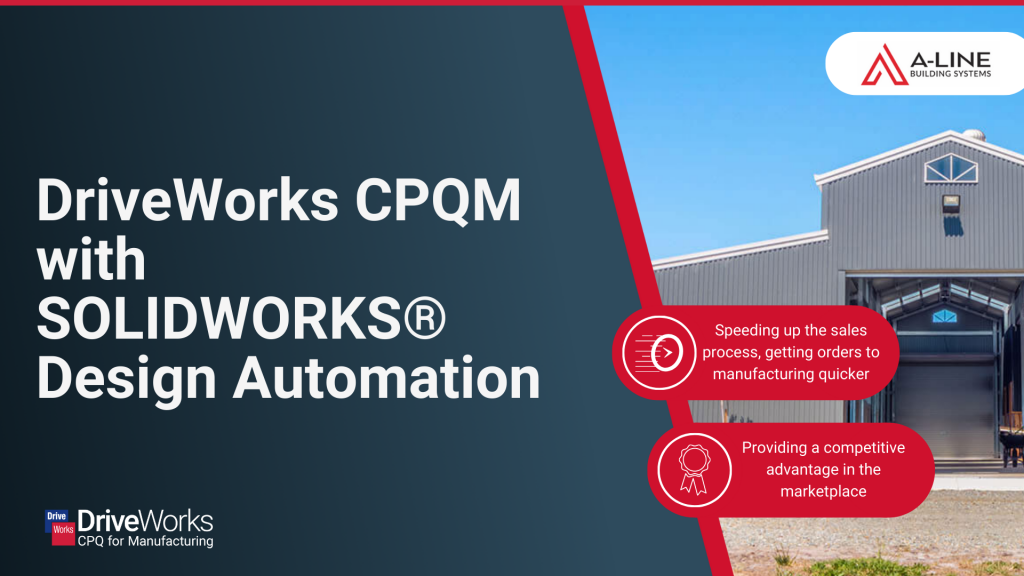

Using DriveWorks design automation and CPQ technology, A-Line Building Systems, a market-leading manufacturer of steel buildings, sheds, barns, carports, and farm outbuildings is reducing errors and saving time, enabling them to focus on quality and professionalism.

“Automating our quoting process using DriveWorks has helped us to save time and money, and reduce errors, without compromising on quality or professionalism.”

Craig Barker, Director at A-Line Building Systems