Configuring a Custom Bi-Fold Door

Implementing an online sales configurator enables your customers, engineers, and sales teams to configure their product, get quotes and place their order in one session.

Many manufacturers are taking advantage of this platform to embrace digital selling and improve overall customer experience.

At the same time, by having a tool like DriveWorks in place they are saving valuable time on repetitive designs, reducing errors, and getting to market quicker with their products.

Manufacturers using DriveWorks rules-based software can embrace digital transformation to improve customer experiences and make selling these custom products quicker, easier and more profitable.

The DriveWorks Live website has many examples showing the latest DriveWorks technology in action. Anyone can use the online configurators, created using DriveWorks software.

In this blog, we’re using one of the examples and following the quick and easy steps to configure a custom Bi-Fold Door online.

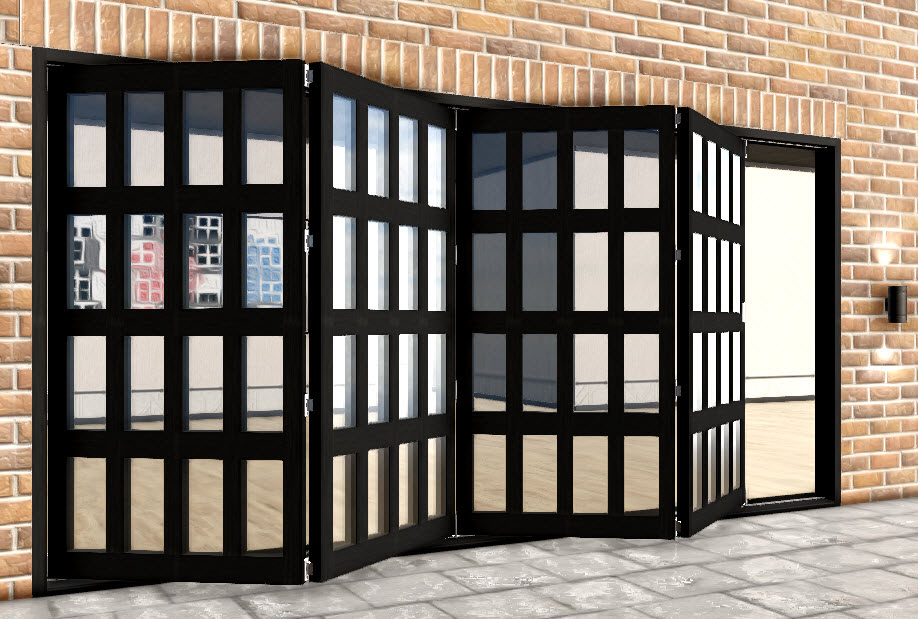

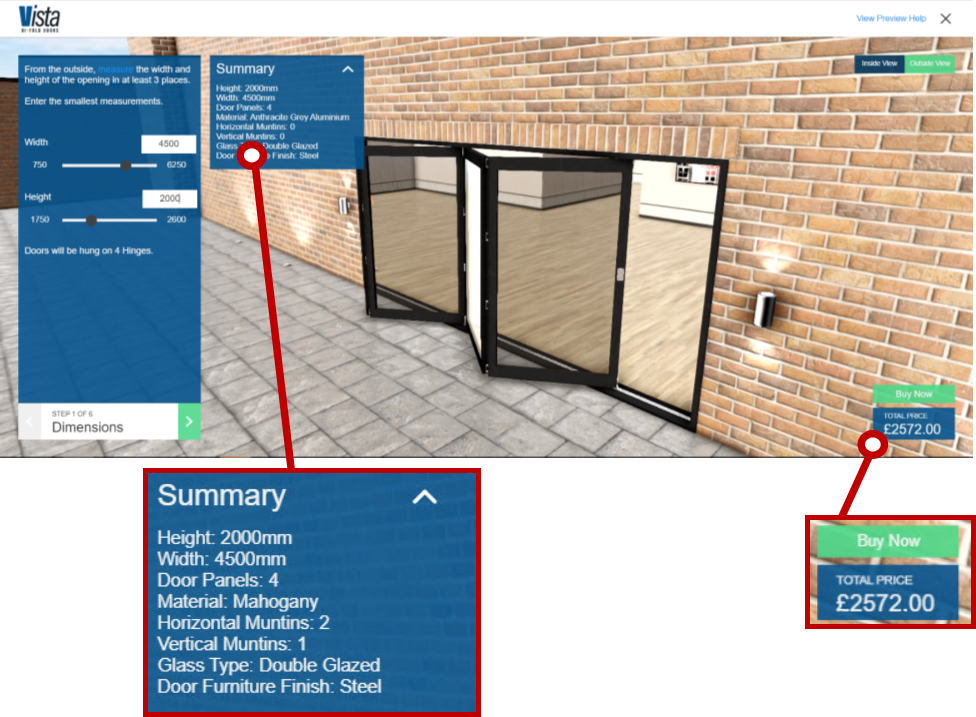

With DriveWorks 18, our team added more 3D capability to bring the doors to life. We’ve positioned the door in a scene to give it context and a more realistic feel.

I’m going to step through a series of options as we design the door, we experience many of the dynamic functions that you can take advantage of when creating your own online sales configurator.

We will complete forms and enter measurements for the door. We will determine how many windows we would like in the door and be able to choose the construction materials.

With every change I make and every option I select, DriveWorks software is working in the background to update the model on screen, update selections and show an up to date price throughout.

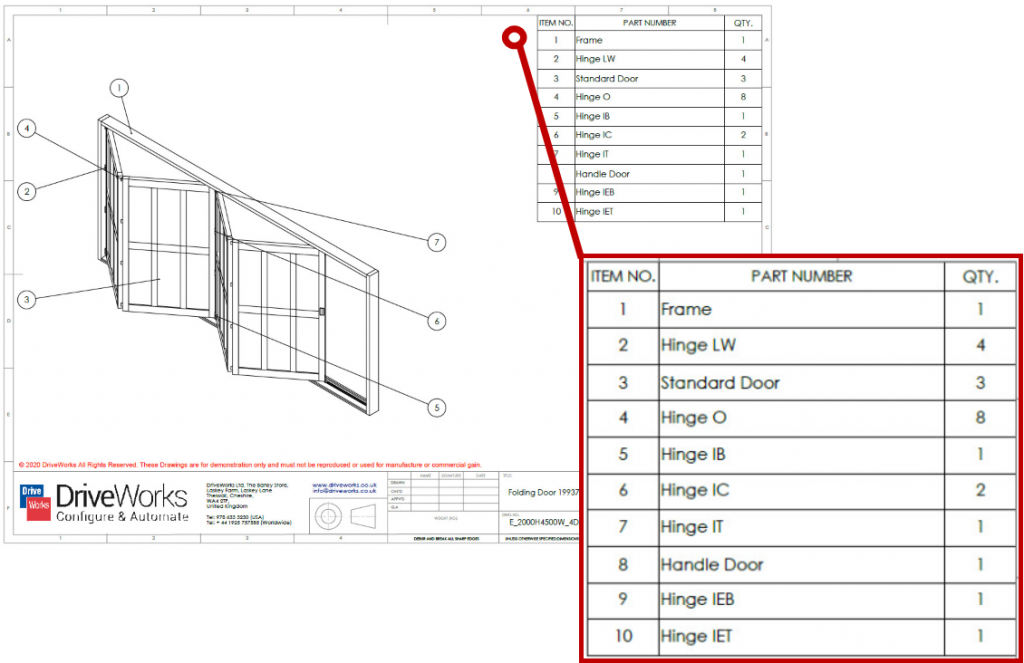

Once I’ve completed my selections, DriveWorks will create all the manufacturing details automatically. That includes the SOLIDWORKS 3D parts, assemblies and drawings, cut lists, BOM and much more.

Interactive 3D

The bi-fold door is in a 3D environment that gives the customer a real-life experience as they are designing their product.

The 3D environment created in DriveWorks allows the customer to zoom in or zoom out and rotate to get a different perspective on the layout of the door.

The door will open and close when clicked with the mouse. This animation makes the bi-fold door example more interactive and responsive.

All these interactions add to the overall 3D experience and create more involved customer engagement. It also gives the customer a clear and realistic perspective on how the door may open and close once installed.

This interactive 3D technology is a key feature in DriveWorks 18. It’s just one example of how you can use the functionality inside DriveWorks to build a 3D product configurator.

Guided Selling

Users can configure the door to their exact requirements, starting by entering the width and height of the door.

DriveWorks provides a guided selling environment to help the consumer work through each step in their design.

This is very helpful as it lets the consumer understand what is needed and be able to complete the steps self-sufficiently.

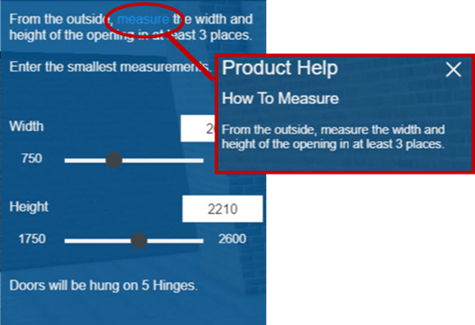

Step 1 asks for the required dimensions. The ‘measure’ hyperlink brings up a pop up that gives the guidance needed to enter the correct information into the form.

Similar guidance is provided throughout the design process. You can decide whether or not to add these helpful pop-ups and make them specific to your products and options.

DriveWorks Form Controls

Forms are the user interface (UI) of a DriveWorks configurator. They are set up in DriveWorks by adding form controls and using rules in the background to decide what to show and when.

Creating an interactive UI in DriveWorks is easy. You can choose from more than 20 “out of the box” control types (label, drop down, slider tool, date picker, etc.)

They are customizable and you can adapt and reskin them to match your own branding.

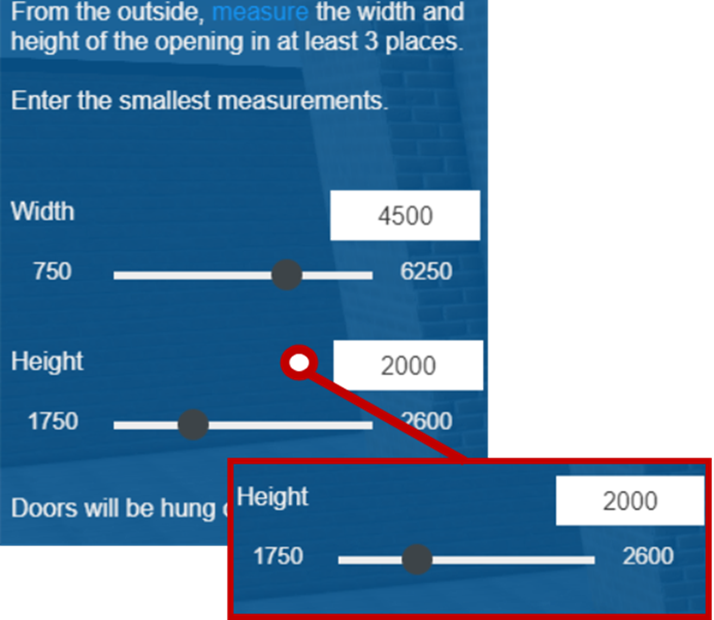

In this example, a slider tool and text box are used for the dimensions. DriveWorks offers multiple ways to create form controls that suit your needs.

Whether it’s entering measurements like the dimensions in Step 1 of this design, or in subsequent steps where we need to enter other design inputs, rules in the background establish minimum and maximum measurement limits and other options.

These rules mean customers, sales teams and distributors can only configure products that can be manufactured, and the calculated outputs are correct.

When changes are made, the rules drive the design to change immediately and displays the updated model.

This is a great tool for the self-guided selling process, but also in a face-to-face sale.

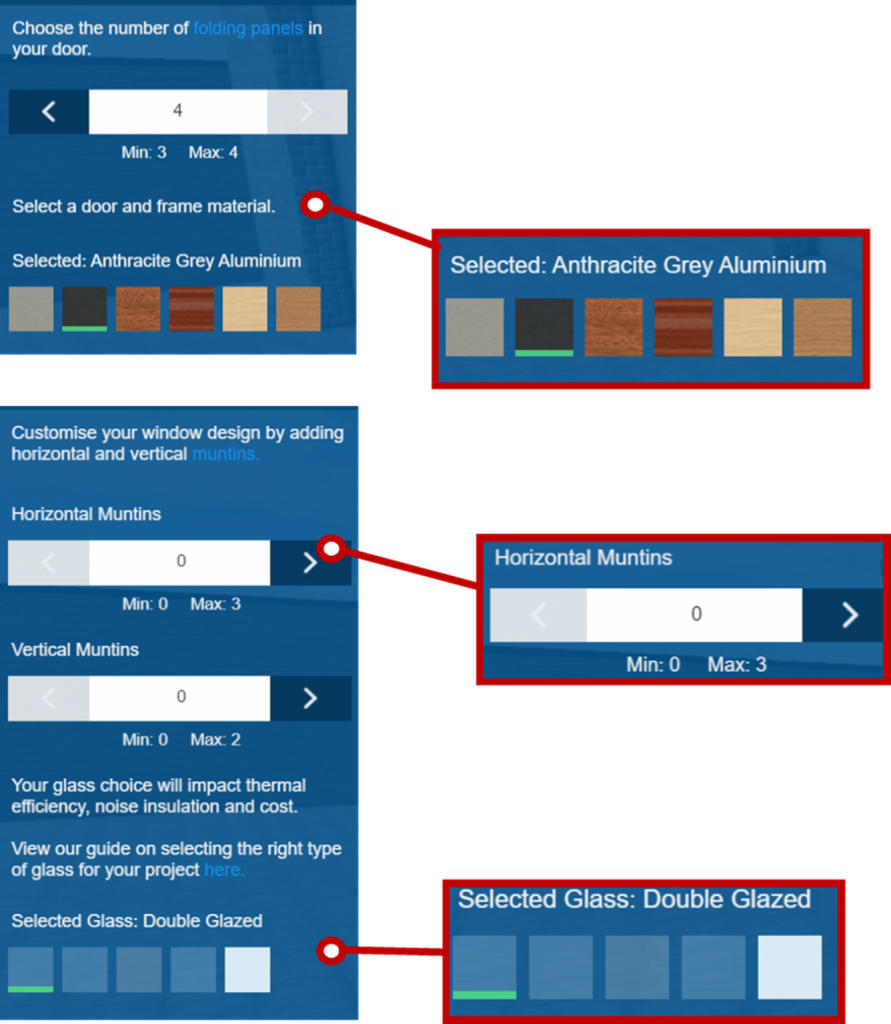

Choosing Components

The number of folding panels, construction materials, muntins (both horizontal and vertical), glass type for the windows and the hardware finishes for the door can all be configured and customised.

These component selections are made using the most appropriate DriveWorks Form Controls for these design options. These are just an example of the many form control options available in DriveWorks, you can see other form options in the Custom Picture Frame Configurator as well as the Cupboard Configurator.

As selections are made, the choices are captured in DriveWorks and applied to the design.

As DriveWorks has fully automated SOLIDWORKS, the changes are applied to the sales order, the CAD model and all associated manufacturing documentation as well.

Live Design Summary and Cost Updates

The sales configurator provides a rolling summary of the custom design. The summary is available throughout the process to view the dimensions and materials chosen as well as the glass type and finish applied to the model.

As it is dynamically linked to the rules running in DriveWorks, if changes are made, the summary and model are both updated in real-time. In addition to the design summary, a real-time update on costs associated with the design is displayed in the bottom right corner.

With the simple-to-use forms it’s quick and easy to design multiple versions of a bi-fold door. Here are just a few examples of doors designed in minutes using this DriveWorks example.

It’s not just the sales configurator that is updating, but the CAD models and all technical drawings and documentation are also automatically generated by DriveWorks.

As there are rules and logic in the DriveWorks project, engineering does not have to check every detail or make changes manually.

Imagine the time saved in engineering by having these designs automated by DriveWorks – time that now can be used to grow other areas of the business.

Not only is it a time saving to engineering, DriveWorks provides an immediate quote to the customer and it reduces errors that could be made by making manual updates repeatedly.

Automated and Custom Outputs

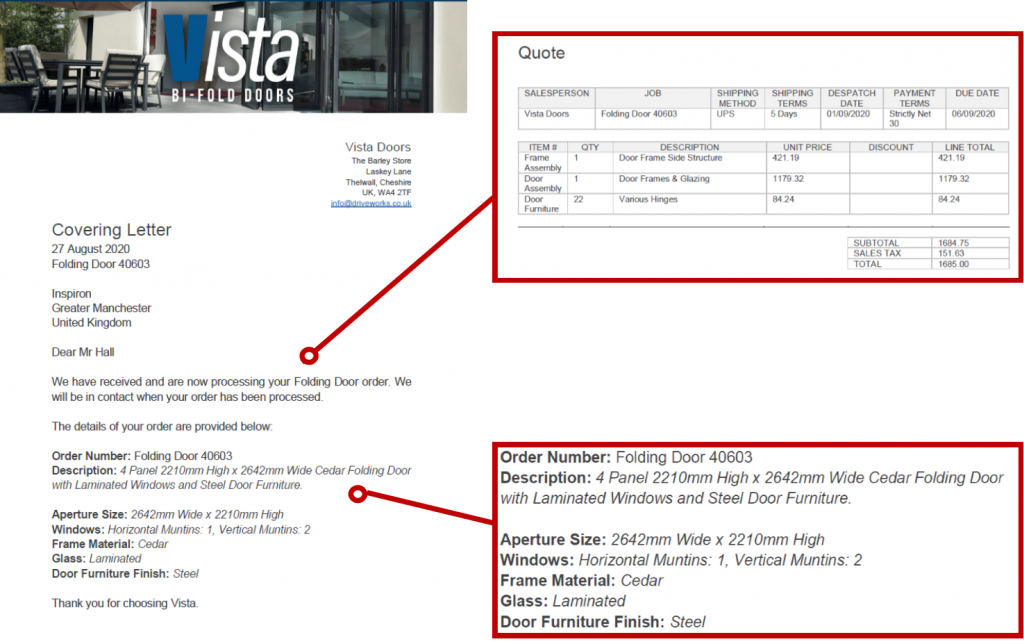

Once the design is complete, a summary screen shows the choices made over the course of the design.

Customers and designers can easily go back into the configurator and make a change to the model, then come right back to this screen to place the order.

Once the order is submitted, DriveWorks immediately begins to generate unique and order-specific sales and manufacturing documents. Within seconds an order-specific cover letter and quote document are sent via email.

As a business, it’s important to have different areas of your business connected. DriveWorks can be easily connected to 3rd party business systems such as CRM, ERP or other database systems.

Passing data to and from other systems and between teams allows everyone to work together and have one unified, cohesive source of information. Having better control and flow of information creates stronger data integrity for the customer and the business.

Immediate Confirmation

Once finished the order is submitted, DriveWorks immediately generates order-specific sales and manufacturing documents.

A cover letter and quote are both sent via email to the customer and the sales team.

A fully dimensioned drawing is generated automatically, saving valuable engineering time. The Drawing, Bill of Materials, Cut Lists and other files are sent to the manufacturing department so manufacturing can begin.

As the rules, logic and engineering knowledge have already been entered into DriveWorks, manufacturing can begin without engineers checking every detail and making changes to the design.

Rules mean customers, sales teams and distributors can only configure products that can be manufactured and the calculated outputs are correct.

The process is fully automated to reduce errors, improve quality and allow product designers and engineers to focus on innovating and improving.

Flexible, Scalable and Easy to Use

DriveWorks is versatile, fully customisable and easy to use so you can build a product configurator that suits your needs.

This Bi-Fold Door configurator is just one example of how DriveWorks can be used and shows just some of the functionality available.

Have a go with this example, and see the many other product and industry examples at www.driveworkslive.com

Once you’ve explored how DriveWorks looks from the front end, head to the Technology section to take a look under the hood at the underlying technology inside DriveWorks and the functionality used to build a Design Automation and Sales Configurator solution.