Glen, CEO of DriveWorks and Maria, VP were invited to the ‘Digitising Bridges’ dissemination workshop at Cambridge University’s Laing O’Rourke Centre for Construction and Engineering Technology.

Digitising Bridges

Laing O’Rourke have been working on a project to develop a set of design configuration tools for bridges. The tools will create a smoother digital process for the design, manufacture and assembly of bridges, reducing the time it takes to complete a bridge.

Laing O’Rourke chose to develop the tools using SOLIDWORKS and DriveWorks, to automate the manufacture of a set of standardised, validated parts and sub-assemblies for the most common bridge types.

They recently showcased the tools at an event at Cambridge University. We were honoured to be invited along to see the project revealed.

Dissemination Event

The event was held at King’s College in Cambridge University, where Scott McGovern, Digital Engineering Leader at Laing O’Rourke talked about the project. The event gave the team the opportunity to review and gather feedback on the tools, their capabilities and the development process to date. They also reviewed the research they have conducted and the impact of digital technologies on the construction industry.

It was so exciting to be part of an event showcasing how DriveWorks is being used to transform the design process for an entire industry. We always like to see how our software helps our customers to work smarter. Seeing it on this scale was inspiring and filled us with such a sense of pride in the software we work hard to develop.

Of course it’s not just about the software. The team at Laing O’Rourke have worked hard to get the tools to where they are today and it’s great to see that this work will benefit the entire bridge industry.

The Project

The project was set up to develop a unified digital delivery process for the bridge industry. The project configures bridge designs from a set of key inputs and a library of parametric components.

The output is a fully coordinated 3D model, with a pack of data generated automatically alongside it. The data pack contains bridge methodologies, and cost and programme data – a single source of truth for the whole bridge lifecycle.

The project is a collaboration between Laing O’Rourke, Tony Gee & Partners and Cambridge University. It is part of a £5.6m funding competition led by Innovate UK, drawing on the UK’s evolving expertise in BIM enterprise.

This is the first time a project of this scale, with this much potential for efficiency, has been attempted in the industry. According to Laing O’Rourke’s Explore Manufacturing director, Alan Clucas, the project is being driven by High Speed 2’s desire to create a “new way” of standardising bridges.

Back in June, the BIM hub spoke with Laing O’Rourke Partnership and Innovation Leader, Engineering Excellence Group, Adam Locke. He talked about the tangible efficencies, and time and cost savings a smoother workflow would deliver. Adam agreed this would be particularly valuable for projects like HS2.

The Outcomes

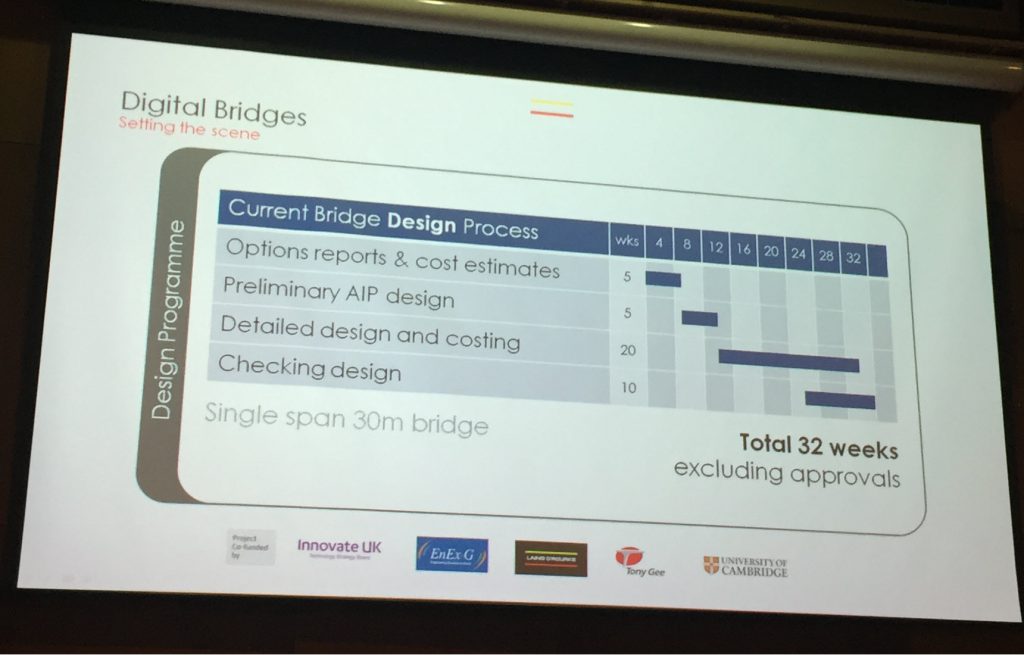

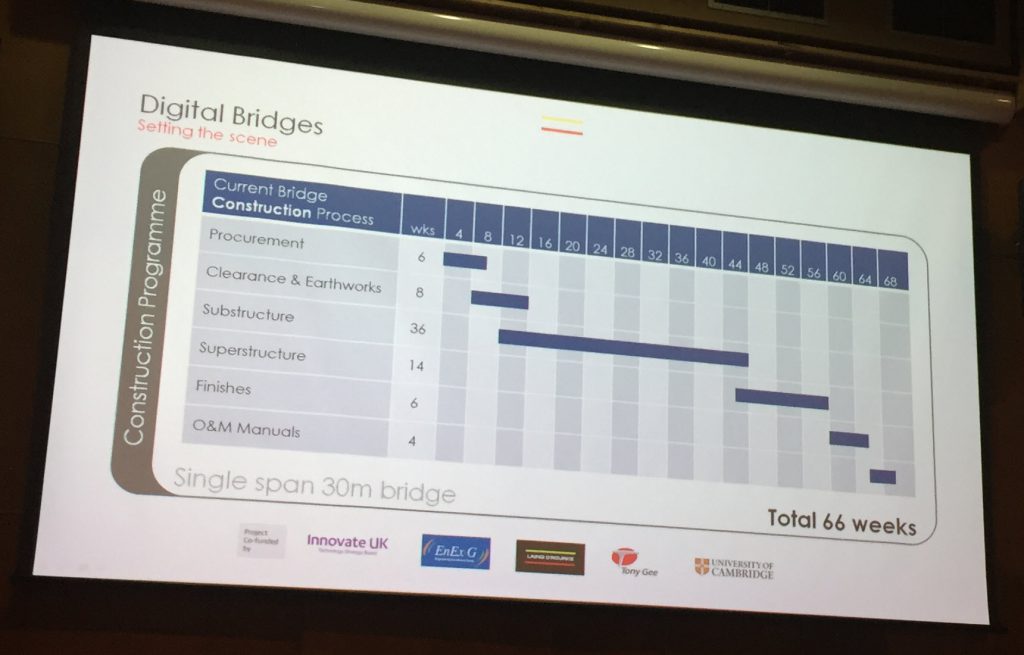

The project uses standards to simplify bridge processes and reduce the time it takes to complete a bridge. Currently the design process is complex, for a single span 30m bridge it takes 32 weeks (excluding approvals). The construction of the same bridge then takes a further 66 weeks.

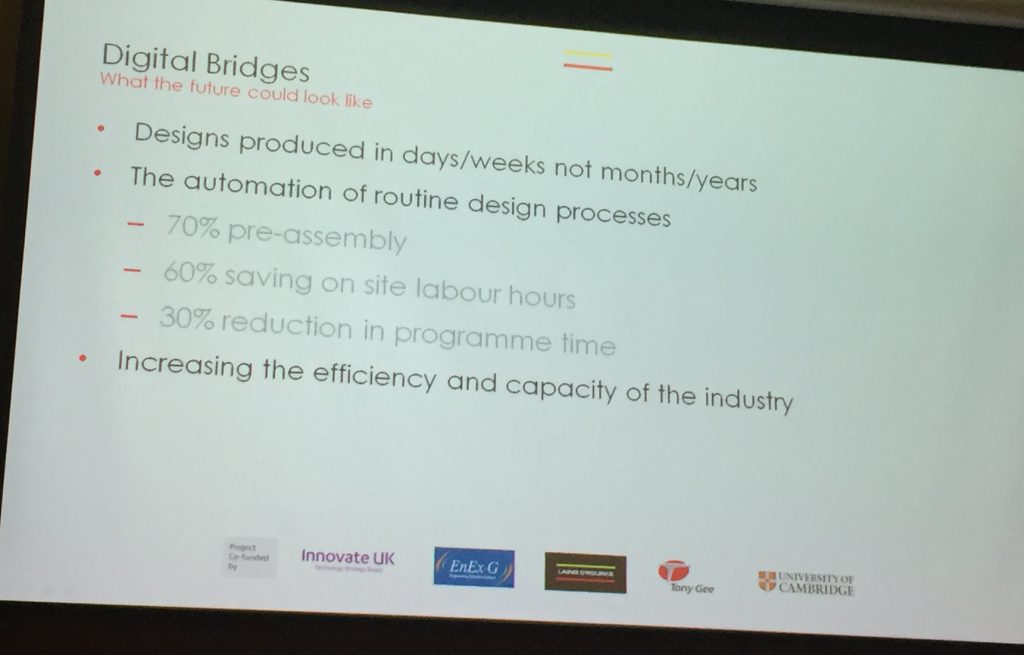

By digitising bridge design with this project, Laing O’Rourke have identified savings that could see bridge designs produced in days or weeks instead of months and years. Rolling out the project will increase efficiency and capacity across the entire industry.

A Common Standard

Adam Locke said the process for designing bridges changes often as most bridges are bespoke. “They are designed by different consultants in slightly different ways, rarely enabling the benefits of offsite manufacture and rapid onsite construction.”

He says the key focus of the project is about creating a common standard, synchronising data and protocols. The aim is to improve interoperability between different parts of the bridge building process.

The project integrates best practices for manufacturing, assembly and design, to ensure consistent data formats and eliminate any manual processes between stages.

For this to happen, naming conventions and output files from each stage of the process need to be structured and arranged in a systematic way. Using DriveWorks, Laing O’Rourke can specify rules to determine how and where each file is saved.

Starting Small

Laing O’Rourke started small with their project, firstly identifying the appropriate segments of the bridge market to automate.

Speaking with the BIM hub, Adam Locke explained they knew they couldn’t focus on everything initially. Instead they looked at the base components for bridges, which can be assembled in a variety of different ways. To ensure a standard across the industry, the project enables them to define the components, select them and combine them in the original design.

DriveWorks software is modular and scalable so for every DriveWorks project, we recommend companies ‘start small’ and add to it over time. Even at this scale, Laing O’Rourke have recognised this is the best practice.

Eventually, the project will cover all aspects of designing bridges and the research delivered could also inform the processes for other parts of the construction industry too.

Read the full interview with Adam Locke, Laing O’Rourke Partnership and Innovation Leader, Engineering Excellence Group, from the BIM hub here.