Karpen Steel

DriveWork Pro allows Karpen Steel to improve efficiency and concentrate on winning more orders and providing great customer service.

Challenge

Due to the extent of technical data involved for each custom order, design processes took a lot of time. Karpen Steel needed a way of ensuring that employee time spent on each order was as efficient and effective as possible, without compromising on quality and accuracy.

Solution

Karpen Steel purchased DriveWorks Pro and built a product configurator and SOLIDWORKS® automation solution to streamline their processes. The amount of employee time needed to process each order has been reduced and the process is now slicker and more efficient.

Results

Guided selling and built in error-checking minimizes disruptions to the order flow. Karpen Steel’s engineering team are freed up from simple, repetitive tasks to focus on the more critical aspects of the order. Documents are created automatically and customer service is improved.

Company overview

Karpen Steel manufactures high-quality custom doors and frames and speciality constructions such as Dutch doors and vision lights. We recently caught up with them to find out how they have successfully streamlined their order process by using DriveWorks Pro.

Challenge

Improving profitability

Being a custom, quick ship door and frame operation, Karpen Steel Custom Doors & Frames completes many small, one off orders. The average order is typically for two doors and two corresponding frames.

Karpen Steel prides themselves on delivering quality products. Even before using DriveWorks, Karpen Steel had processes in place to track and verify each order.

However, due to the extent of technical data involved for each custom order, these processes took a lot of time. Once an order was placed, it was checked by two members of the customer service team and two engineers, to ensure everything was accurate.

Karpen Steel needed a way of ensuring that employee time spent on each order was as efficient and effective as possible, without compromising on quality and accuracy.

Solution

Automating processes

Karpen Steel purchased DriveWorks Pro and built a product configurator and SOLIDWORKS automation solution to streamline their processes.

The amount of employee time needed to process each order has been reduced and the process is now slicker and more efficient, allowing Karpen Steel to concentrate on winning more orders and providing great customer service.

Once an order is received, the customer service team enters the parameters of the order into the DriveWorks configurator. This then creates the 3D SOLIDWORKS model and order documents for both the customer and the workshop, whilst also generating the price for the order and placing the order or quote as a database entry – all in one simple step.

Results

Reducing errors and driving consistency

The form within the DriveWorks Pro Configurator guides the user through the order process, they only see, and are only prompted to fill out, the relevant fields on the form for the product line selected.

The ability to set up error checking within DriveWorks Pro also prevents the user from leaving out required information or entering parameters that can’t be manufactured.

In addition, the configurator forms have been designed to provide feedback to whoever is filling them out, by using pictures, pop up warnings and instructions that help catch errors before the order progresses to the next step.

This helps to minimize the number of times orders must be returned to customer services due to incomplete or inaccurate information, which would disrupt the order flow.

Automating manufacturing outputs

As DriveWorks automates SOLIDWORKS, the customer service team are effectively now using its powerful 3D capabilities, without the need for any SOLIDWORKS training.

It means that Karpen Steel’s engineering team are freed up from simple, repetitive tasks to focus on the more critical aspects of the order.

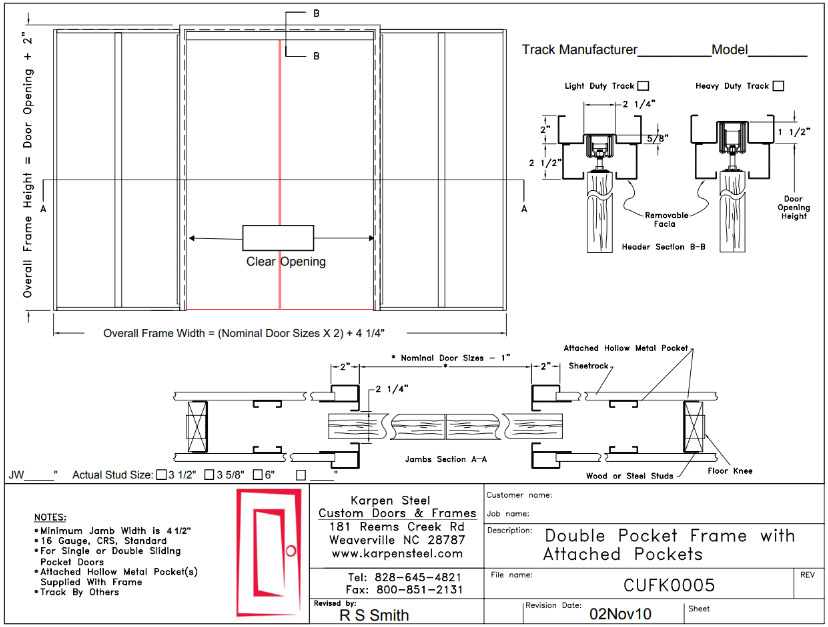

DriveWorks Pro also saves time by creating all the required documents, which contain images specific to the order details such as the frame profile, anchor types, hardware locations and door vision light size and placement.

These documents are then sent to both the customer and the workshop, with each document being designed for the recipient’s unique needs. In both, potential errors or required changes can be quickly identified, and then this feedback is passed to the shop personnel.

Try DriveWorks Pro configurator examples online.

Request a demo with a technical specialist

Fill out the form below and a member of the DriveWorks team will be in touch.

This form is currently unavailable, please email sales@driveworks.co.uk for assistance.